CNC Machining for Automotive Camshafts by TOP Prototype

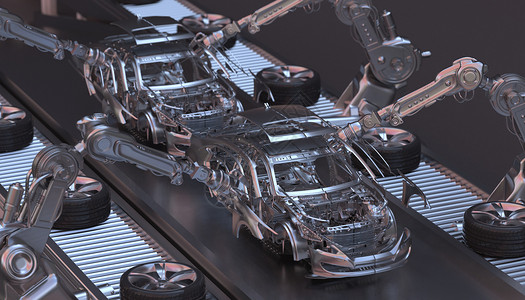

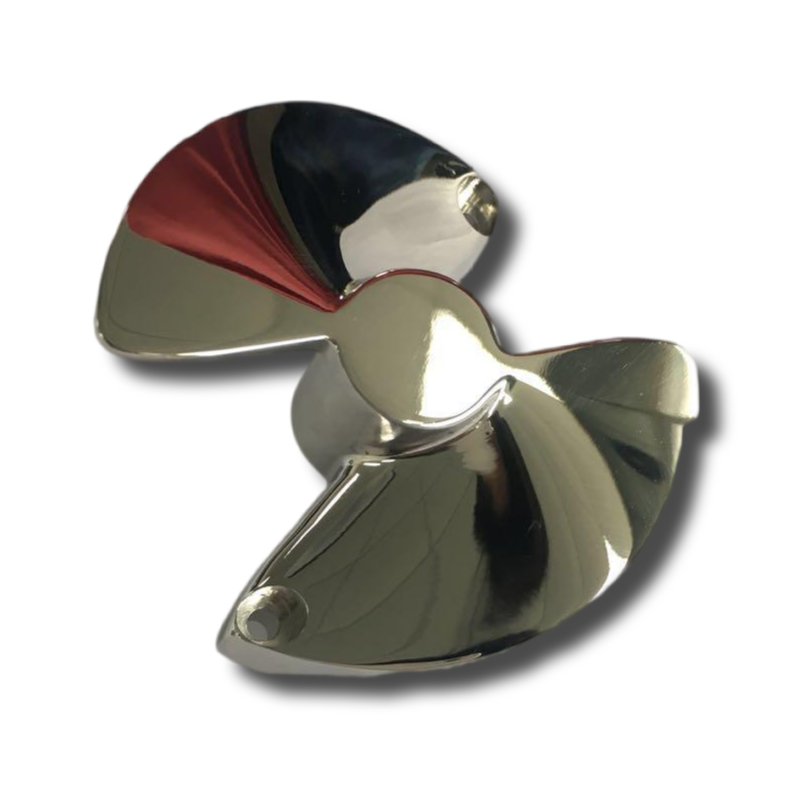

Precision Redefined: CNC Machining for Automotive Camshafts by TOP Prototype Every high- performance automotive engine has a core component: the camshaft. It acts as the “brain” of the valve train. It controls the timing and lift of engine valves. This directly impacts combustion efficiency, torque output, and overall engine performance. Advanced automotive engineering relies heavily on CNC (Computer Numerical