Quality Assurance of TOP Prototype

Ensure that your prototypes and on-demand production components have high quality, high precision, and durability

Pre-production

Technical Evaluation:Before the production stage begins, our engineering team will conduct a technical evaluation of your part design. This includes the assessment of important factors such as materials, surface finish, structure, processes, and other details of 3D and 2D drawings.

During Production

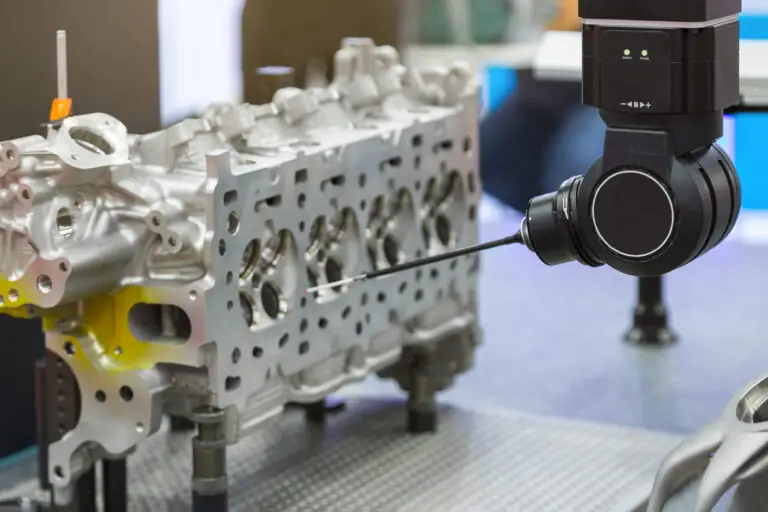

On-site Inspection System:In precision machining, the machining materials must always be in the correct position. With the on-site inspection system, the position can be automatically checked and adjusted accordingly. The use of the on-site inspection system helps avoid problems at an early stage, thereby saving costs and time.

Final Finished Product

Full-size Inspection Report:For all orders, we provide a full-size inspection report upon request. This report will include the following contents: number of parts, key dimensions, threads and tolerances, thickness and depth, part appearance, etc.

About production -RSPO standard

Quality Reports on Your Request

Quality Reports

For each order we receive, we can secure a list of quality reports per your request

Inspection report

Full dimensional report

Material test report

Certifications

As an established manufacturer of on-demand products, we have a library of certifications from reputable organizations.

ISO 9001:2015 ROHS REACH

Quality Control Process

Full-dimensional inspection report

For all orders, we provide full dimensional inspection report on request. This report will include the following: quantity of parts, critical dimensions, threads and tolerances, thicknesses and depths, part appearance, etc.

Packaging

Ensuring that the parts we manufacture are of the highest quality is important. We know about the unpredictability of logistics. Therefore, we make sure we lower the risk to the parts during our packaging process. Four layers of protection: 1. wrapping paper 2. EPE 3. foam 4. paper/wooden box are applied during the packaging process, ensuring that we deliver the most high-quality and beautiful parts to you.

Own factory - integration of industry and trade

Our factory is equipped with cutting-edge tools and technologies. Professional team has skilled CNC machines, powerful injection molding equipment (up to 830 tons), laser cutting machines, bending machines, welding machines, and modern 3D printers, etc. Our production line is automated, ensuring that every product we manufacture is efficient and accurate. Through in-house management manufacturing, we pay close attention to the quality of each step. This helps us maintain high standards, provide flexible production plans, and offer cost-effective solutions without sacrificing quality.

Quality Inspection Equipment

To facilitate our strict quality control, our production facility has special workshops for careful inspection and advanced equipment. We do thorough inspections at each production stage to make sure every component is precisely made as per your specifications.