Injection Molding Service

Custom injection molding services for plastic prototypes and on-demand production parts. Get a free injection molding quotation and design feedback within hours.

No minimum order quantities

Rapid Tooling Production as fast as 2 weeks

ISO 9001:2015 certified

24/7 engineering support

- Home

- CAPABILITIES

30t-1800t

Molding Machine

12

Surface Finishes

0pc

MOQ

0.05mm

Tolerances

Our Injection Molding Capabilities

From plastic prototyping to production molding, RapidDirect’s custom injection molding service is ideal for the manufacturing of competitive pricing, high-quality molded parts in a fast lead time. Strong manufacturing facilities with powerful, precise machines ensure the same mold tool for creating consistent parts. Better yet, we provide free expert consultation on each injection molding order, including mold design advice, materials&surface finishes selection for your end-use applications, and shipping methods.

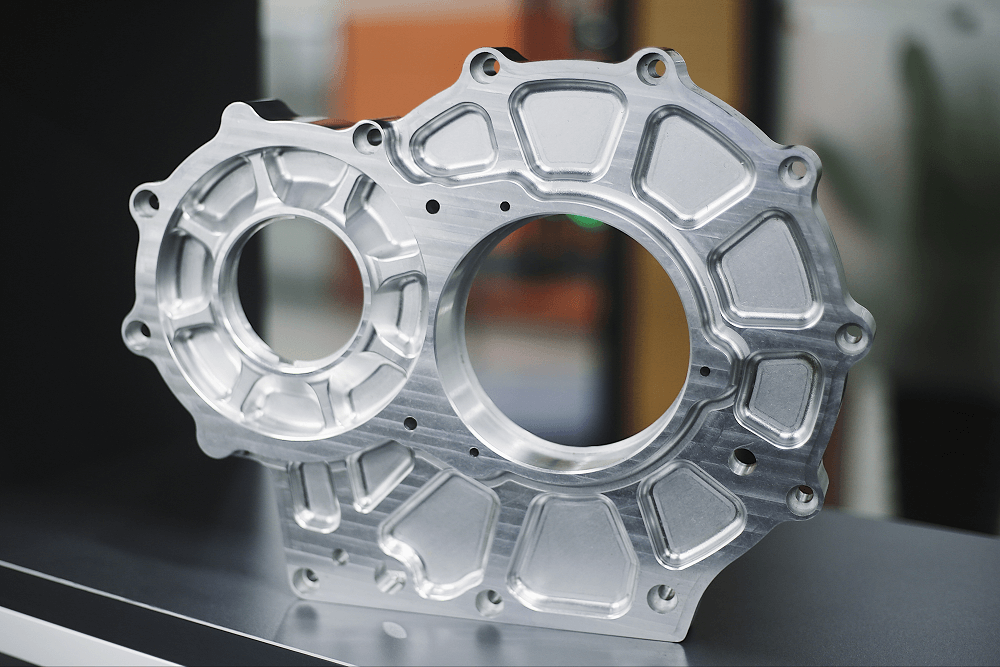

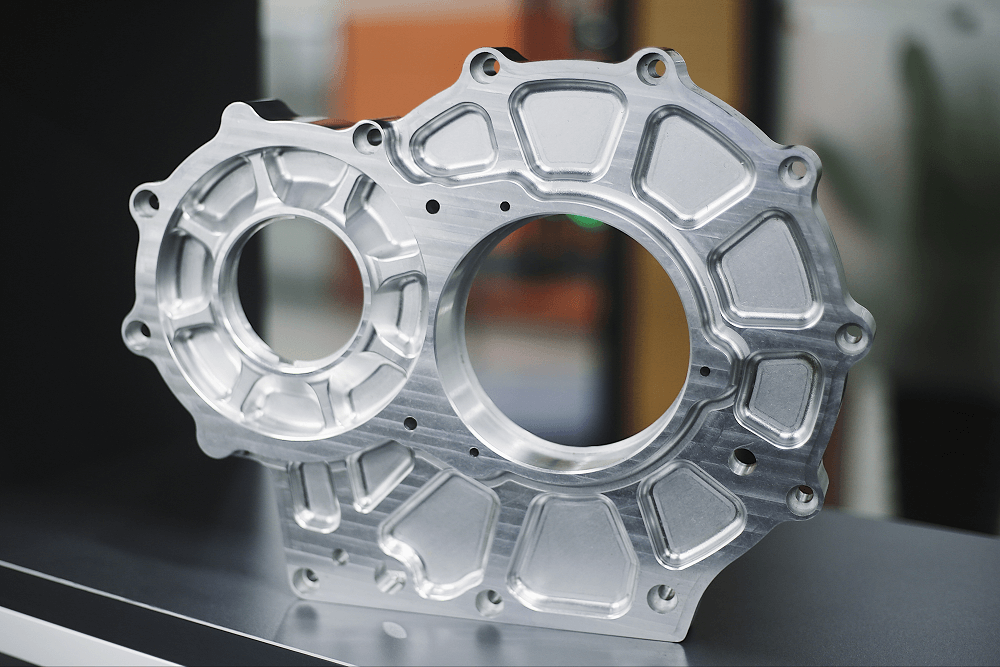

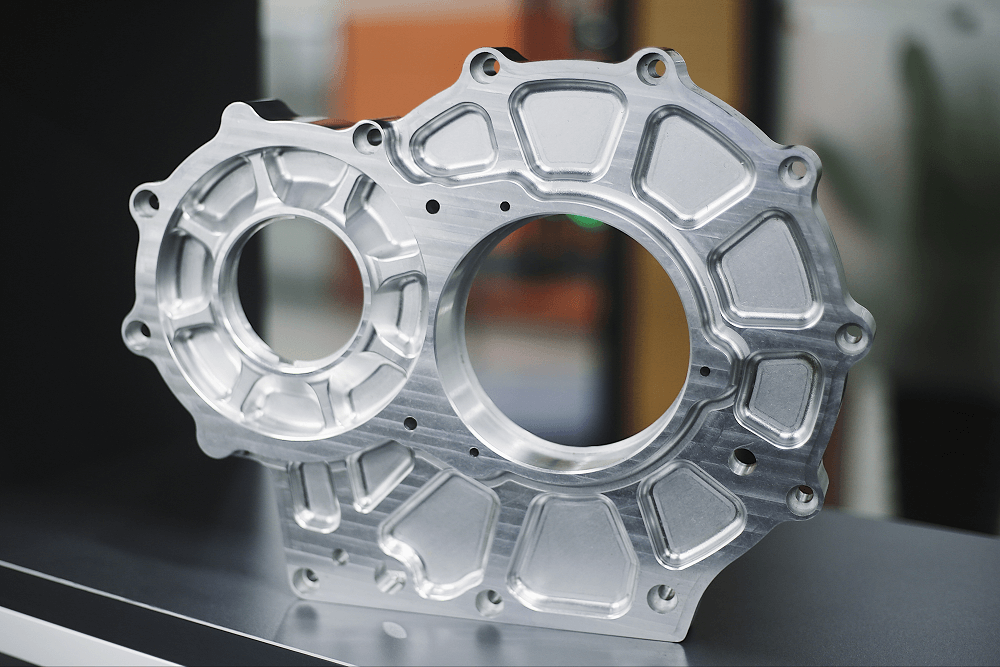

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, RapidDirect’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, RapidDirect’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, RapidDirect’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, RapidDirect’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

Our Injection Molding Processes

See how we process your orders, from quotation to tooling, as our machines and efficient team ensure you receive your molds and parts within the scheduled lead time.

Request for Quote

Request your quote from our online quotation platform and our dedicated engineers will provide a response within 24 hours, ensuring the process goes on smoothly.

DFM Report

To ensure we can produce functional molds, we offer feasibility reviews of your design to ensure we can fulfill requirements before starting production.

Mold Flow Analysis

Predictive modeling software helps us look at the way molten material moves and acts within the mold, which helps us deliver improvements.

Mold Tooling Production

Start the production of mold tooling according to your specific application needs by using the materials and finishs of your choice.

T1 Sample Verification

T1 sampling will be delivered for you to review prior to manufacturing plastic parts to ensure precision and quality.

Low Volume Production

After completing the trial production phase, we proceed to low volume production, utilizing advanced machining techniques to manufacture parts quickly and efficiently.

Strict Inspection

A strict inspection process, including the inspection of function, dimension, and appearance, ensures that the parts meet the required specifications and are of high quality.

Delivery

After a thorough inspection, we will deliver your products to you as quickly as possible while ensuring their safety.

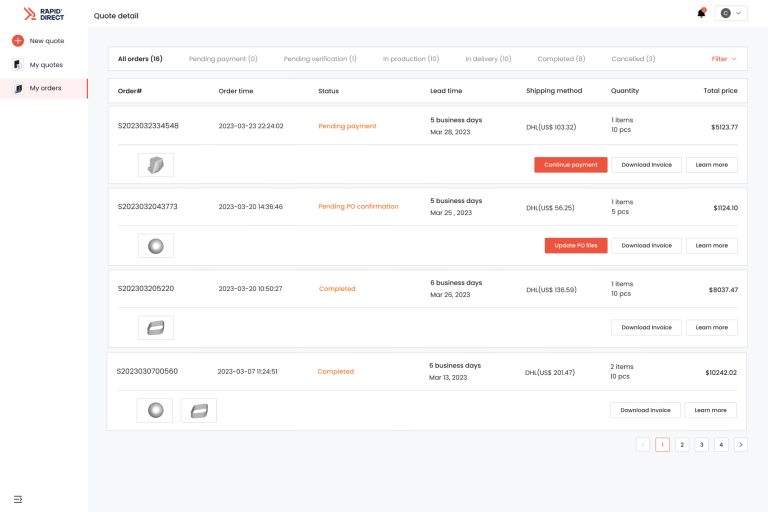

Quote Within One Day, Operate at Your Fingertips

RapidDirect provides a AI-powered, hassle-free online quotation platform that can help simplify your ordering and manufacturing process. Stop wasting time in emails, get interactive quotes with DFM analysis within seconds, optimize your orders immediately, compare your multiple quotes side by side, manage your orders in one place.

Bulk Pricing

Real-time Order Tracking

All-in-one Order Management

From Prototyping to Production

Rapid Prototyping

With our instant quotation platform and robust manufacturing capabilities, we can deliver exceptional prototypes within short lead times. This enables you to quickly test prototype parts and bring them to market faster.

Bridge Production

Minimize the disparity between the design of a part and the eventual launch of the product. Our skilled engineering team to offer valuable design recommendations for your production parts, ensuring practical solutions for your needs.

RapidDirect Injection Molding Capabilities

| Standards | Description |

|---|---|

| Maximum Part Size | 1200×1000×500 mm; 47.2×39.4×19.7 in. |

| Minimum Part Size | 1×1×1 mm; 0.039×0.039×0.039 in. |

| Part to Part Repeatability | +/- 0.1 mm; +/- 0.0039 in. |

| Mold Cavity Tolerances | +/- 0.05 mm; +/- 0.002 in. |

| Available Mold Types | Steel and aluminum tooling. Production grade we provide: Under 1000 cycles, under 5000 cycles, under 30,000 cycles, and over 100,000 cycles |

| Machines Available | Single cavity, multi-cavity, and family molds, 50 to 500 press tonnage |

Class of Injection Molding Mold

At RapidDirect, we design and create precise custom injection molds from high-quality materials. Our processes ensure unmatched consistency and repeatability at fast lead times and affordable pricing. Every plastic injection molding we fabricate meets international standards. From one-off projects to small batches and production tooling, we provide durable and reliable mold tools.

| Mold Class | Purpose | Shot Life | Tolerance | Cost | Lead Time |

|---|---|---|---|---|---|

| Class 105 | Prototype Testing | Under 500 cycles | ± 0.02mm | $ | 7-10 days |

| Class 104 | Low-volume Production | Under 100.000 cycles | ± 0.02mm | $$$ | 10-15 days |

Materials for Injection Molding

These are commonly molded plastics that our injection molding service provides. After knowing the basics of materials, like common grades, brands, advantages, and disadvantages, choose the right injection molding material depending on your application requirements.

Tooling Materials

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 Stainless Steel: 420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Note: You can learn more from our eBook on plastic materials.

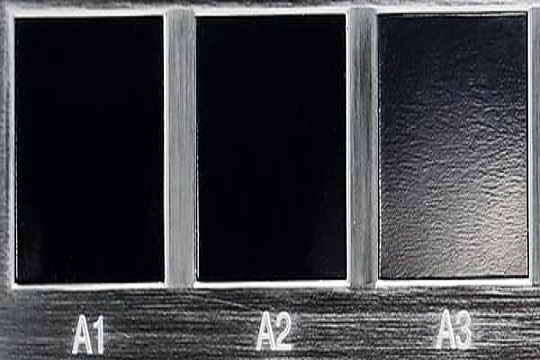

Surface Finishes of Injection Molding

Injection molding includes injection mold tooling, plastic injection molding, and more. The surface treatment of the mold is usually completed during the production process. After the injection molding is completed, we will carry out certain surface treatments on the finished product as per your requirement.

| Name | Description | Link | |

|---|---|---|---|

| Glossy | A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. | Learn More>> |

| Semi-glossy | B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. | Learn More>> |

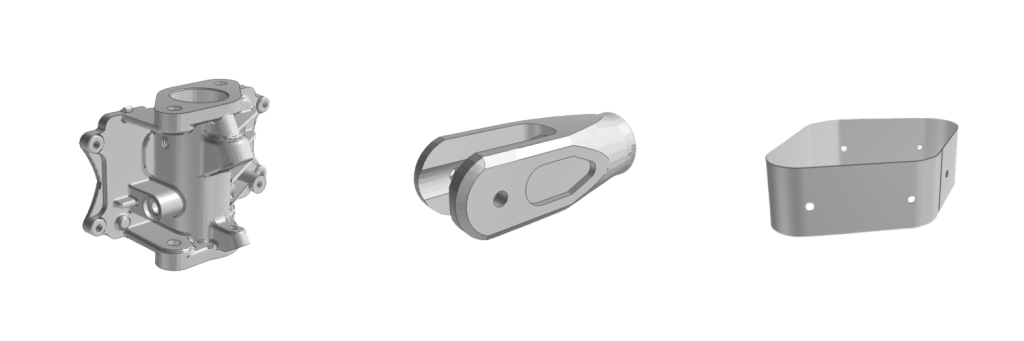

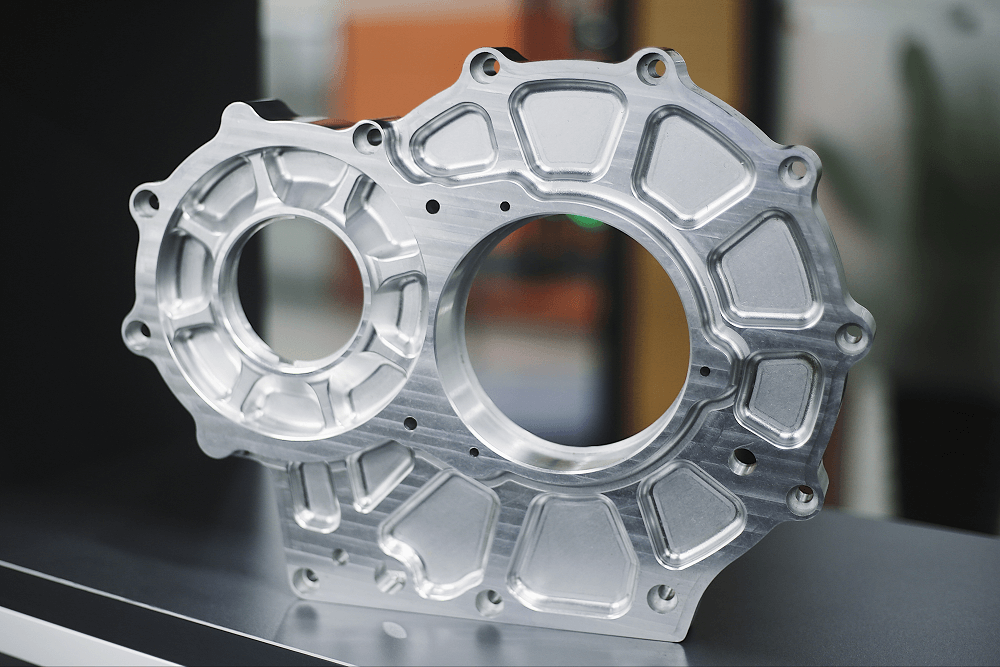

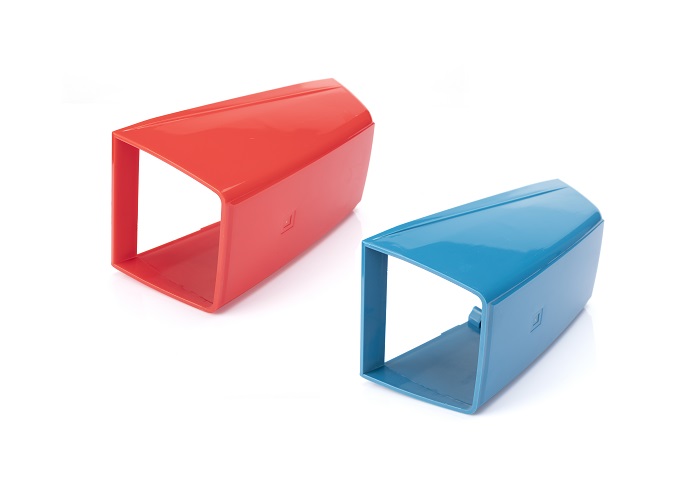

Gallery of Injection Molding Parts

Dive into RapidDirect’s extensive gallery that showcases some of our completed injection molded parts and take confidence that we can create your injection molding project according to your strict specifications.

Gallery of Injection Molding Parts

No MOQ

No minimum order requirement helps move plastic molded parts from design to production in a fast turnaround and supports your on-demand molding manufacturing needs with reduced injection molding cost.

High Efficiency

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your injection molded parts as fast as possible.

Consistency and High Quality

Owing certified factories, conducting in-process inspections and dimensional verification after production, guarantee the custom molded parts are consistent in quality regardless of the complex shape with high precision.

Injection Molding Specialists

Working with our experts having 10+ years of experience in the injection molding industry, efficiently complete a turnaround from prototyping to production.

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

Ready to Get Your Custom Injection Molding Quotes?

Learn what you need before requesting for quotes for your injection molding projects at RapidDirect. Help you get wonderful molded parts made effectively, easily.

Automotive

Automotive

Automotive

Automotive

Automotive

Let's Start A New Project Today

See What Our Customers Say About Us

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Explore Related Resources

CNC Machining of Engineering Plastics by TOP Prototype

CNC Machining of Engineering Plastics by TOP Prototype TOP Prototype is a leading company in the field of precision manufacturing, …

TOP Prototype CNC Machining of Metal Materials

TOP Prototype CNC Machining of Metal Materials CNC machining plays a crucial role in the manufacturing industry, especially when …

TOP Prototype CNC Drilling: Precision and Efficiency in Modern Manufacturing

TOP Prototype CNC Drilling: Precision and Efficiency in Modern Manufacturing In the realm of modern manufacturing, Computer Numerical Control …