3D Printing Service

3D printing is suitable for rapid prototyping and production parts. Order and send us your 3D model for custom 3D-printed parts today to receive an instant quote by the next day.

The fastest processing parts 1 day

Multiple materials available for processing

Technical support and design guidance

- Home

- CAPABILITIES

- 3D PRINTING

1

1 hour Instant Quotes

3

3 days Lead time

1

1 pcs MOQ

0.01mm

0.01mm Tolerances

3D Printing Service at Top Prototype

TOP Prototype combines professional expertise to enhance and accelerate your innovation strategies while delivering high-quality products at an affordable price. Our custom metal 3D printing services specialize in three 3D printing technologies: SLA, SLS, and FDM. Each of these technologies has its unique features, such as high precision, cost-effectiveness, suitability for complex models, and rapid prototyping. The choice of technology depends on specific printing needs, including precision, materials, cost, and application scenarios. As a result, custom 3D printing is widely applied in industries such as healthcare, industrial manufacturing, and aerospace.

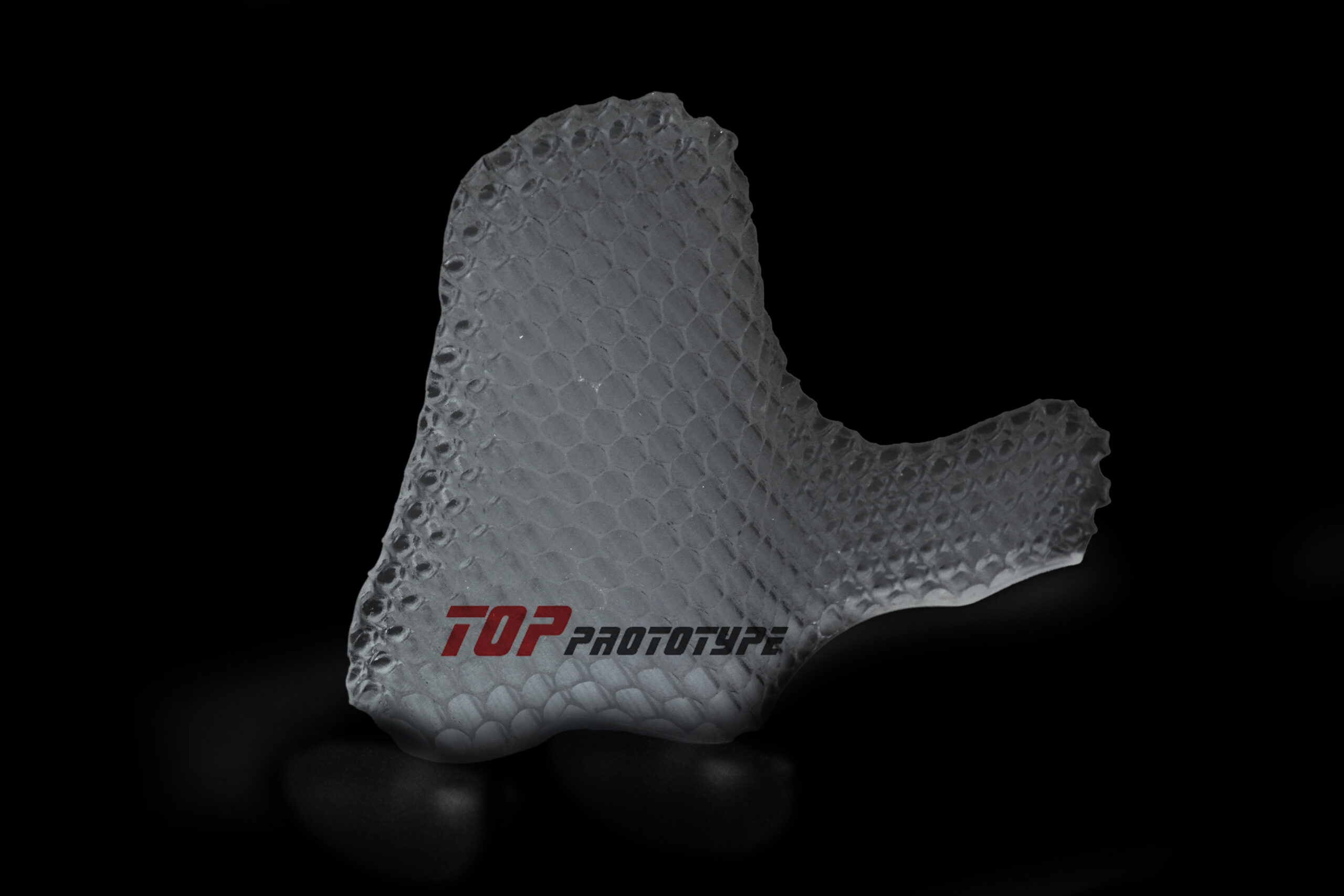

SLA

Stereolithography uses photopolymerization to make parts.< BR>

The technique uses the right light source to interact with the material in a selective way, solidifying the cross section of the object into a thin layer.

SLA technology can print complex structure models with high precision and smooth surface, and is widely used in medical, aerospace, jewelry design and other fields.

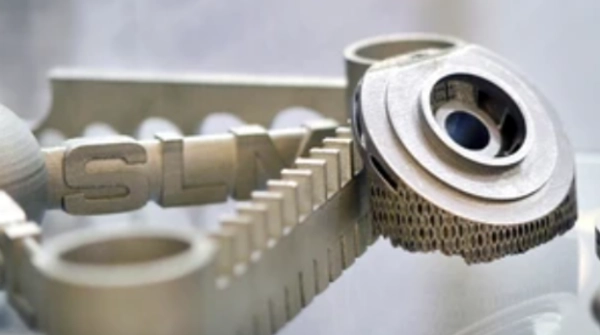

SLS

Selective laser sintering (SLS) 3D is a technology where the material is heated, but not to the point of melting, to create high resolution items.

Metal powder is used for direct metal laser sintering while thermoplastic powders are used for selective laser sintering.

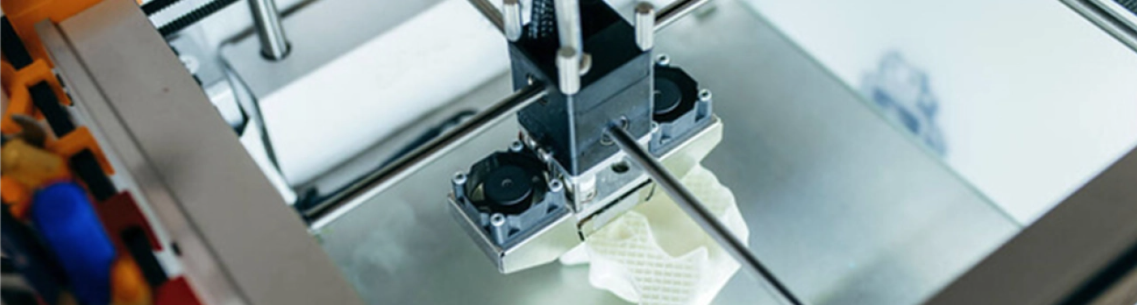

FDM

In 3D printing, Fused Deposition Modeling (FDM) is a common additive manufacturing technology.

It includes powder bed fusion (lays thin powder layers and uses lasers to melt and solidify along a path), electron beam melting (uses electron beam as energy source in high vacuum), and direct energy deposition (melts and deposits material via lasers, arcs, or electron beams for layer-by-layer construction).

3D Printing Machining Parts Display

Explore our display of 3D-printed plastic and metal parts to discover our expertise in 3D printing and post-processing, including precision, quality, and surface finishing techniques. See how various 3D printing technologies are applied across industries, from medical equipment and industrial components to aerospace parts. Whether you have a ready-to-print model or need assistance, don’t hesitate to request a quote! We’ll provide you with a complete and tailored metal 3D printing solution!

Custom Metal 3D Printing Materials

Based on your 3D metal printing project requirements, you can choose from over 50 production-grade materials, each with its unique advantages. For instance, ABS is ideal for applications requiring high-impact resistance and rigidity, such as electronic enclosures and automotive components. Nylon is preferred for its wear resistance, flexibility, and lightweight properties, making it suitable for dynamic and industrial applications. At Top Prototype, our professionals will provide custom 3D metal printing solutions designed to meet your specific needs and requirements. Explore our comprehensive 3D printing materials list, or feel free to contact us to discuss your unique project requirements!

| Materials | Description | |

|---|---|---|

| ABS | High impact resistance, toughness, and rigidity. |

| Nylon | Flexibility,toughness ,lightweight and has a low friction coefficient. |

3D Printing Processing Surface Treatment

At TOP Prototype, we offer a wide range of 3D printing post-processing techniques tailored for both functional and aesthetic purposes. Each method comes with specific requirements, including material compatibility, color options, texture preferences, and budget considerations. Below is an overview of the 3D surface finishing techniques we provide to enhance your 3D-printed parts.

| Process | Description | |

|---|---|---|

| As-Machined | As machined is ideal for functional prototypes or internal components without aesthetic requirements. Quick production for testing and development. |

| Painting | Painting offers many color choices and finishes, enhancing the aesthetic appeal of plastic products. It also provides protection against scratches and UV rays, increasing durability and longevity. |

| Polishing | It smoothens the surface of 3D printed objects, enhancing their aesthetic appeal and reducing roughness. Polishing can be done manually or using specialized machines, and it helps improve the overall quality and finish of the printed parts. |

| Electroplating | The electroplating coating enables the reduction and deposition of metal cations by applying an electric current, which can protect the surface of the parts and prevent corrosion caused by rust and other defects. |

Why choose our 3D Printing service?

Our 3D metal printing service offers high precision, enabling the creation of parts with tight tolerances and fine details that meet the strictest quality standards. We handle complex designs with ease, allowing us to produce intricate geometries, internal structures, and overhangs without the need for additional support structures, which would be difficult or impossible with traditional manufacturing methods. This design freedom lets us create lightweight, optimized components with superior strength-to-weight ratios.We provide 24/7 engineering support, ensuring that our expert team is always available to assist with your 3D printing design optimization, material selection, and troubleshooting, guaranteeing the best possible results for your project.

High precision standard

Delivers parts with tight tolerances and fine details, achieving standard tolerances of ± 0.05mm.

Handle complex designs

3D metal printing technology in our service easily handles complex models.

24/7 engineering support

Our expert engineering team is available to assist with your order 24/7.

FAQ

3D printing is a kind of additive manufacturing through which three-dimensional objects can be produced based on 3D drawings. It is also called additive manufacturing (AM).

In addition to SLA 3D printing service, we do offer other popular 3D printing rapid prototype services such as SLS, SLM,FDM, etc.

Types of Printing Material. 3D printing materials can vary widely, with options that include plastic, powders, resins, metal and carbon fiber. These materials make 3D printing a promising option for many parts, from highly accurate aerospace and industrial machinery components to customized consumer goods.

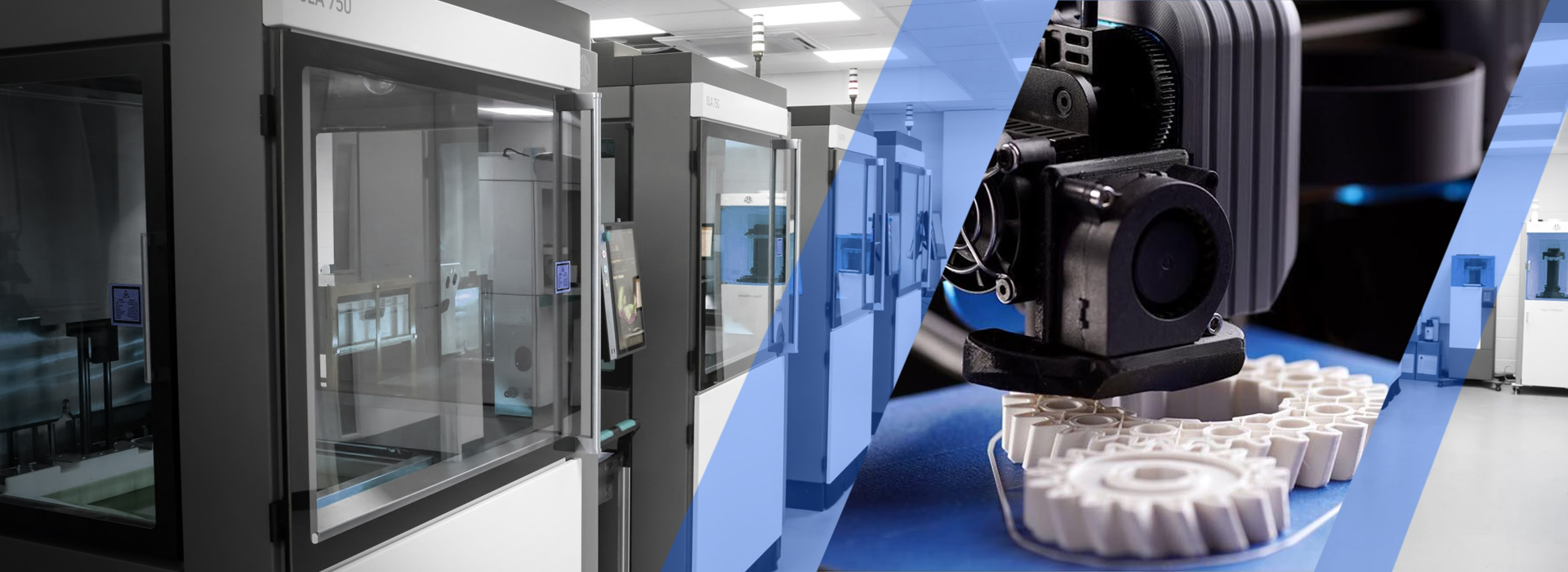

3D Printing Equipment

TOP Prototype implements strict quality control protocols to ensure that every customer receives high-quality products.

Advantage of 3D Printing

Customization: At Top Prototype, metal 3D print services allow for high levels of customization, enabling the creation of unique, tailored products or prototypes to meet specific project needs and industrial applications.

Complex Geometries: Our metal 3D printing service can easily create complex shapes and intricate designs that would be difficult or impossible to produce with conventional methods. The best part is, we can add this complexity without incurring additional costs into the custom 3D printing parts service.

Durability: Since the metal materials used in 3D printing are resistant to high temperatures and corrosion, parts produced by 3D metal printing technology usually have higher strength and are suitable for applications that withstand greater pressure and loads.

Integration of Multiple Parts: Complex assemblies with multiple parts can be combined into a single piece through 3D printing, reducing the need for assembly and potentially improving the strength and durability of the final product.