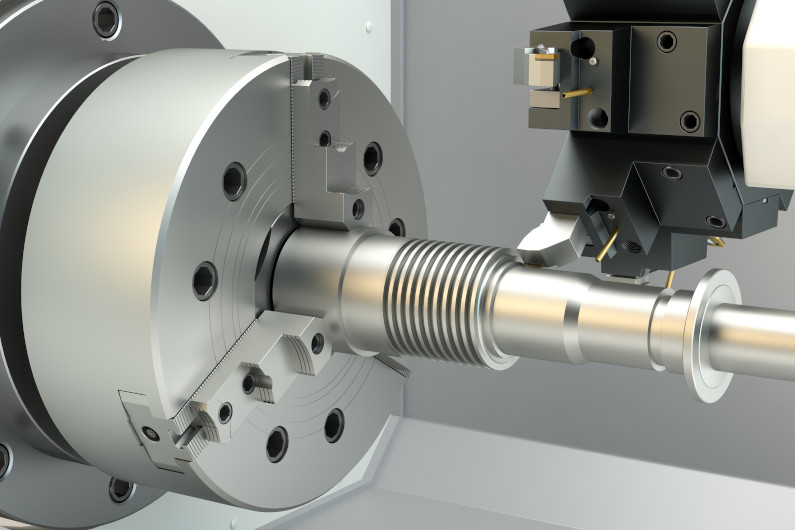

CNC Machining

(CNC Milling/Turning)

CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. It uses sharp cutting tools, available in a variety of shapes and sizes, which are precisely controlled by a computer.

Tolerances as tight as ±0.0004" (0.01mm)

Processing parts in as fast as 1 day

3, 4, 5 axis milling

- Home

- CAPABILITIES

- CNC MACHINING(CNC MILLING/CNC TURNING)

1

1 hour Instant Quotes

3

3 days Lead time

1

1 pcs MOQ

0.01mm

0.01mm Tolerances

CNC Machining Service

Top Prototype is one of the leading manufacturers of CNC machining services in China, specializing in both CNC milling and CNC turning. Top Prototype precision CNC machining services are suitable for both the early development stage and mass production. CNC machining prototype services support complex geometric shape processing as well as cylindrical part machining. Additionally, CNC machining services offer customization with support for over 100 types of materials and finishes, ensuring fast turnaround times and exceptional quality for both one-off prototypes and production parts. Online CNC machining service in Top Prototype enables rapid prototyping and supports both small-batch and large-scale production needs. CNC milling and turning services can be combined to provide the most optimal machining solutions based on the shape and functional requirements of the parts.

CNC Milling

CNC milling of prototype CNC machining is a process that utilizes computerized controls to manage the movement and operation of multi-point rotary cutting tools. As the tools rotate and move across the surface of the workpiece, they slowly remove excess material to achieve the desired shape and size. Standard CNC machines include 3-axis, 4-axis, and 5-axis milling machines. Multi-axis metal CNC machines require no fixed tooling, are highly flexible, and extremely accurate.

CNC Turning

CNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes that have superior surface finishes. Turning is available for products including dial plate drums, rings, shafts, segments & castings. Milling & boring services are also available. When you need precisely manufactured parts, fast turnaround, and no volume limitations. CNC turning at Top Prototype is your best solution

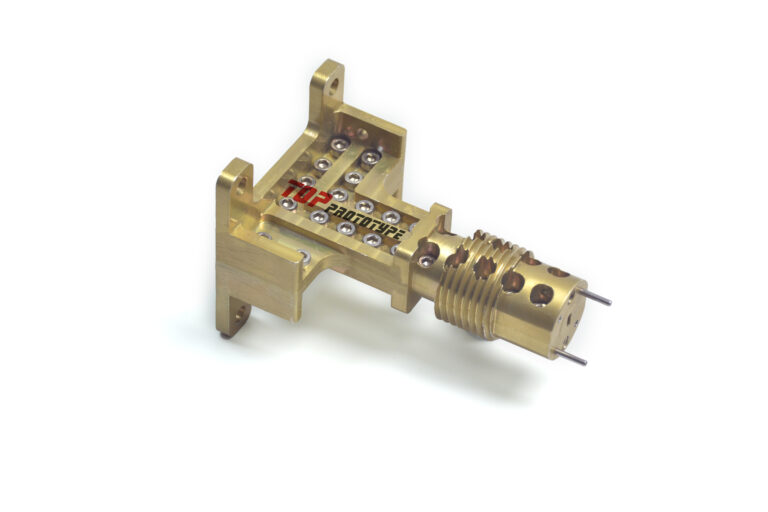

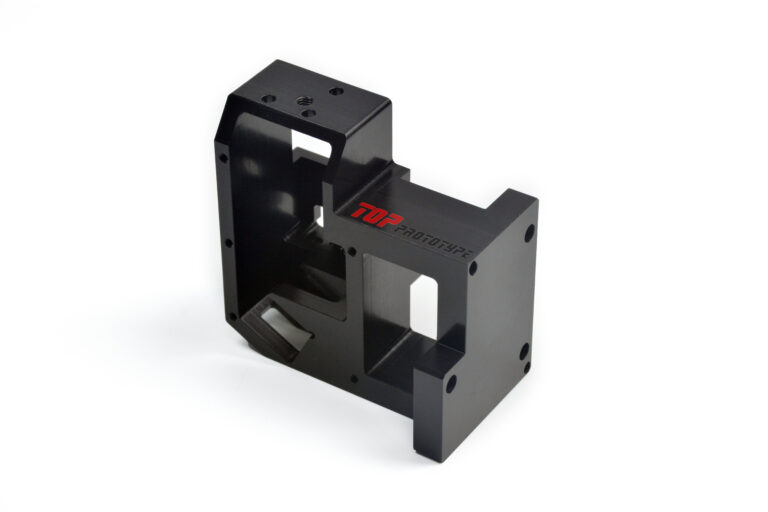

CNC Machining Parts Display

Discover Top Prototype’s online CNC machining services for high-precision parts with complex geometries and exceptional surface finishes.

CNC Produces Machining Materials

According to your needs, you can strictly select from more than 50 types of materials that meet production standards. Our CNC machining service is applicable to various materials from metals to plastics. Please take a look at the CNC Produces machining material list. You are also welcome to contact us to discuss your personal needs.

| Materials | Description | |

|---|---|---|

| Aluminum | Aluminum has an excellent strength-to-weight ratio among these metals. This is an excellent choice for high load requirements on aircraft mounts and enclosures. Aluminum also has good ductility, stiffness, corrosion resistance and workability. Its lightweight properties make it useful in aerospace structural applications such as fuselage skins, wing ribs, wing skins, etc. |

| Copper | Copper has excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and easy to weld. |

| Stainless steel | Stainless steel is a type of mild steel whose properties are sought after in many industrial applications. Stainless steel usually contains at least 10% chromium by weight. They are the first choice for critical joints in engine and exhaust components, landing gear components and aircraft superstructures, ensuring high performance and durability. |

| Titanium | Titanium has many material properties that make it an ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. This metal also has an excellent strength-to-weight ratio. |

| Plastic | Plastic is also a very popular choice for CNC machining because of its wide selection, relatively low prices, and significantly faster machining times. We offer CNC machining services for all common plastics. |

CNC Machining Surface Treatment

Surfacing finishing techniques of CNC machining prototype service both functional and aesthetic purposes. Each technique has requirements, such as materials, color, texture, and price. Below are the surfacing finishing technique rendered by us.

| Process | Description | |

|---|---|---|

| Sandblasting | After sandblasting treatment, the surface of the parts has a matte texture. It is mainly used for visual applications and can then undergo other surface treatments. |

| Anodizing | Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects metal surfaces. Widely used in mechanical parts, precision instruments, aircraft, automobile parts, etc. |

| Electrostatic spraying | Electrostatic spraying is a coating applied as a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporating solvents, powder coatings are typically applied electrostatically and then cured under heat or UV light |

| Polishing | The polishing range spans from Ra 0.8 to Ra 0.1. The polishing technique utilizes abrasive materials to rub against the surface of the parts, leading to the surface of the parts becoming either more lustrous or less lustrous, all depending on your requirements. |

| Plating | The electroplating coating enables the reduction and deposition of metal cations by applying an electric current, which can protect the surface of the parts and prevent corrosion caused by rust and other defects. |

Why choose our CNC Machining service?

Top Prototype provides custom CNC machining services for a wide range of applications and industries, serving over 50 countries and 3,500 companies. Adhering strictly to ISO standards, we consistently deliver high-quality products across our production lines. We offer rapid prototyping, small-batch machining, and large-scale production, with every order supported by Top Prototype professionals from start to finish. Our fast CNC machining capabilities cover both metal and plastic services, combined with flexible production and shipping options to meet your needs at the best price and any stage of product development. Top Prototype operates ISO 9001 and ISO 13485-certified quality management system facilities, providing comprehensive inspection reports to ensure the quality of your CNC-machined parts. If any CNC machining parts fail to meet usage standards, please contact us within 5 business days of receiving your order, and we will provide a solution on the same day, along with a 15-day quality guarantee. We accept technical drawings and have a team of expert technical support to ensure you receive high-quality, cost-effective CNC machined parts on time.

High precision standard

For small batch parts, CNC machining services can achieve standard tolerances of ± 0.05mm.

For parts with higher requirements, we can also achieve ± 0.01mm"

Handle complex designs

TOP Prototype's CNC machining centers are capable of machining a wide range of complex precision parts.

No matter what the material, no matter how difficult, we can create a part to meet your unique needs.

Fast production speed

We have a mechanical workshop with an advanced CNC machining center, which helps us create prototypes and produce small batches of parts within a few days.

Top Prototype High Quality CNC milling machine services

Top Prototype has collaborated and provided CNC milling services with over 3,000 certified and renowned partners, including those accredited by well-established institutions and compliant with ISO 9001:2015, RoHS standards, and comprehensive material testing certifications. With our in-house CNC machining factory equipped with advanced CNC milling machines and state-of-the-art machining technologies, we have the capability to meet diverse manufacturing needs. Our advanced factory ensures that no matter the complexity of your CNC milling parts, we have the expertise and the right equipment to produce it. From simple straight-line designs to intricate geometric shapes, we support 3 to 5-axis CNC milling and right-angle milling, enabling rapid and precise creation of your designs. No matter what your industry is, Top Prototype delivers instant pricing, the fastest lead times, and tailored CNC milling solutions across a wide range of materials and manufacturing processes. Get your instant quote today!

Top Prototype CNC turning machine services

Top Prototype has over 25 years of experience in CNC turning manufacturing, dedicated to delivering the required capacity and capabilities for every project while offering the most competitive pricing and lead times. We provide complete dimensional inspection reports for all orders upon request, ensuring our customers have comprehensive insights into critical dimensions, part appearance, threads, and tolerances related to CNC turning. Our advanced CNC turning machines are equipped to handle rapid prototyping as well as small to large-scale production. Additionally, we have expert advice that supports the entire process, helping customers successfully complete their CNC turning projects. Send us your product files (PDF, STEP, CAD) to receive an instant quote today!

FAQ

CNC machining refers to the machining process proceed by Computerized Numberical Control (CNC for short).It’s a manufacturing process which involves the use of automated rotating cutting tools and lathes to make custom designed metal and plastic parts. Our CNC machines precisely remove material from solid metal or plastic blocks to develop custom parts that can range from simple lines to complex shapes. With this manufacturing process we can develop custom machine parts, prototypes and tooling such as subplates, rotary fixtures, automotive and aerospace fixtures.

Also called precision machining, the CNC machining could reach a very high accuracy in geometical tolerance and dimensional tolerance. With our CNC machines and Horizontal Machining Centers (HMC) and Vertical Machining Centers (VMC), we can almost meet all of your required tolerance grades.

We work with many types of Stainless Steels, Aluminums ,metals and plastics (i.e. Teflon, Delrin, Acetal) and many more.

For CNC machining components, we can have them as machined, de-burred, sanded, polished, painted, silk screened, electroplated, anodized, etc. It all depends on your needs.

CNC Machining Equipment

TOP Prototype implements strict quality control requirements to ensure that every customer receives high-quality products.

We have a specific workshop equipped with the most advanced inspection equipment for the most meticulous verification work.