Die Casting Services

Die casting is a manufacturing process used to produce precisely shaped metal components by injecting molten metal into a steel mold under high pressure. Die casting service usually apply to widely used for creating parts with complex shapes, high dimensional accuracy, and smooth surface finishes. Most industries like automotive, aerospace, electronics, and consumer goods require custom die-casting solutions to meet unique design and performance specifications.

ISO 9001:2015 certification

Tolerances as tight as ±0.004"" (0.1 mm)

Technical support and design guidance

- Home

- CAPABILITIES

- DIE CASTING

1

1 hour Instant Quotes

3

3 days Lead time

1

1 pcs MOQ

0.01mm

0.01mm Tolerances

Die Casting

Die casting is a manufacturing process used to produce precisely shaped metal components by injecting molten metal into a steel mold under high pressure. Die casting service usually apply to widely used for creating parts with complex shapes, high dimensional accuracy, and smooth surface finishes. Most industries like automotive, aerospace, electronics, and consumer goods require custom die-casting solutions to meet unique design and performance specifications.

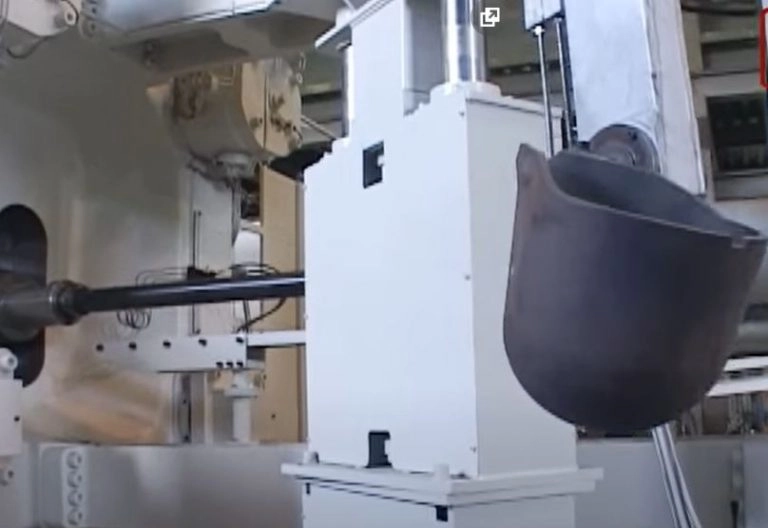

Hot chamber die casting process

Hot chamber die casting is a process that uses low-melting-point alloys to melt the metal through a gooseneck into the mold at injection pressures of 1,000 - 5,000 psi. Suitable for mass production of relatively complex parts.

This process is suitable for zinc alloys, lean alloys, copper and other low melting point alloys.

Cold chamber die casting process

A die casting for high melting point alloys that helps reduce heat in the machine and solves corrosion problems in machine parts and related components by passing the metal through a shot chamber into the mold at pressures of 2,000 to 20,000 psi.

This process is mainly used for high melting point alloys such as aluminum, magnesium, some copper and iron alloys.

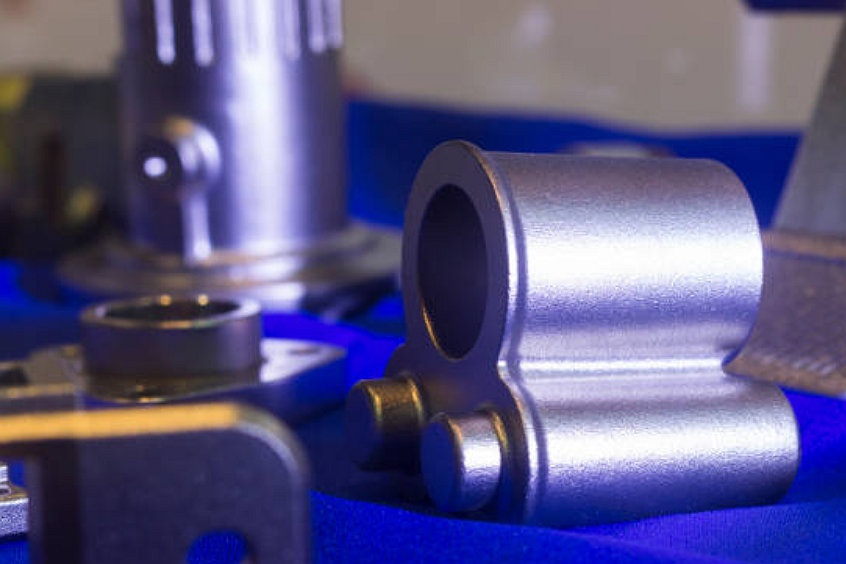

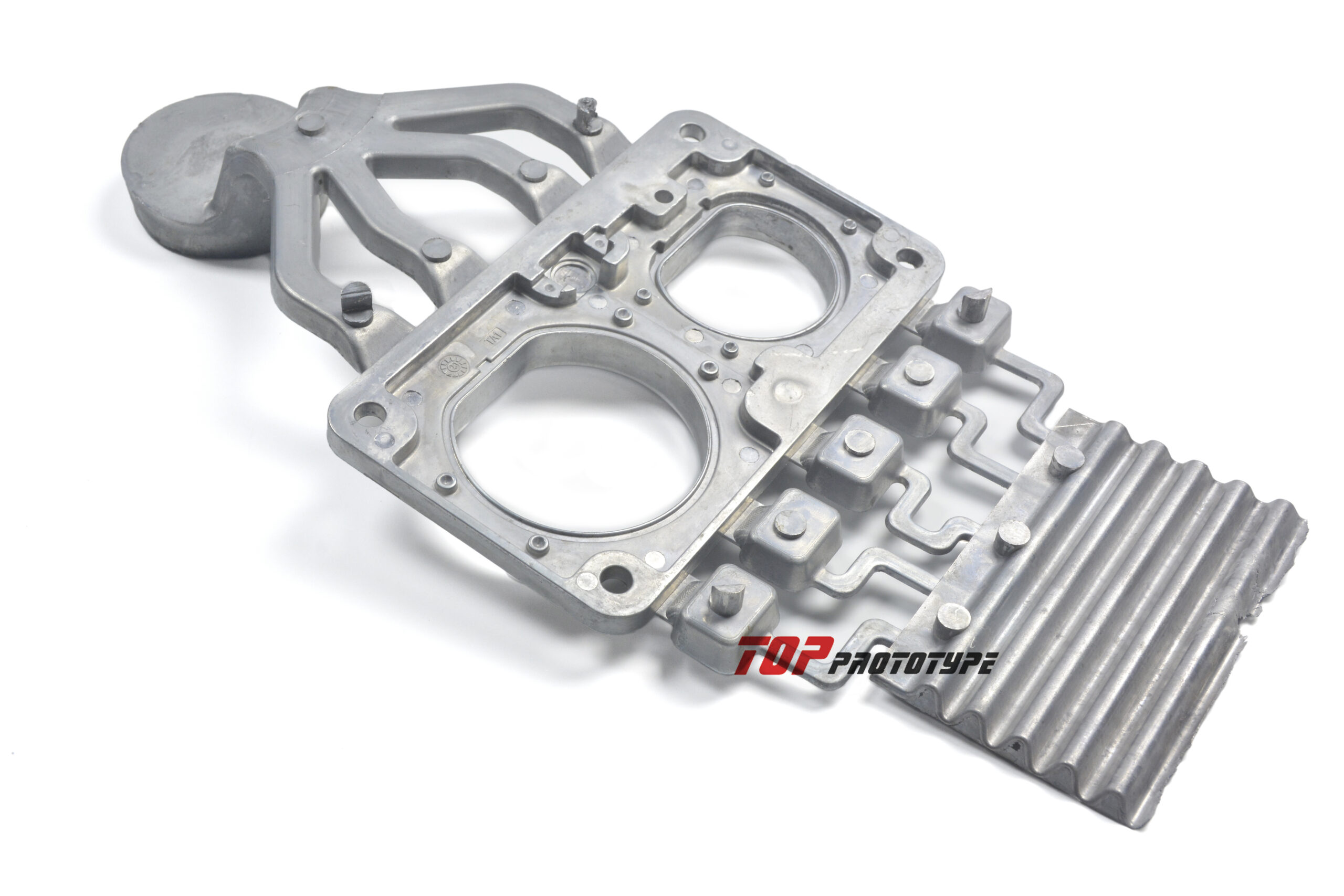

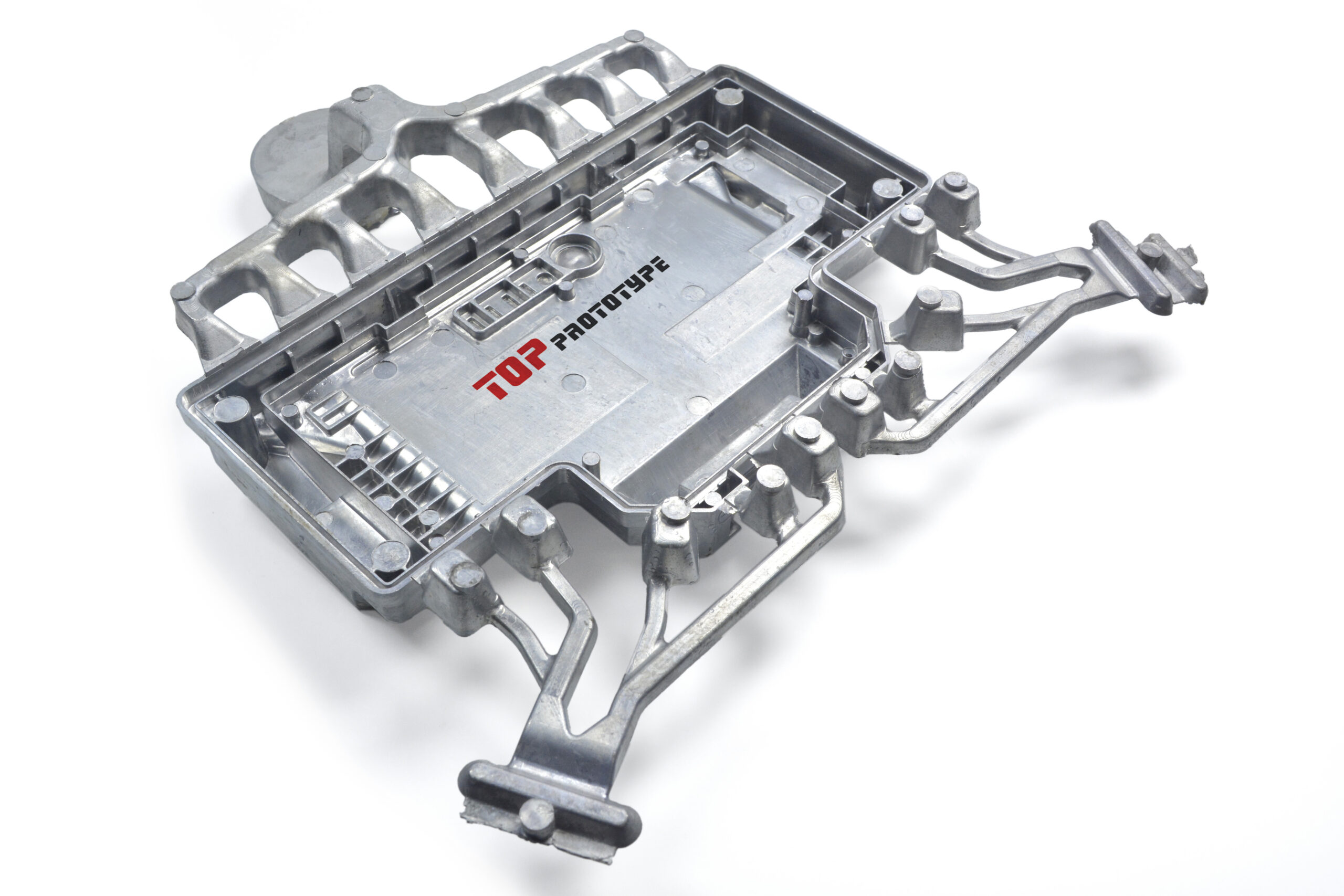

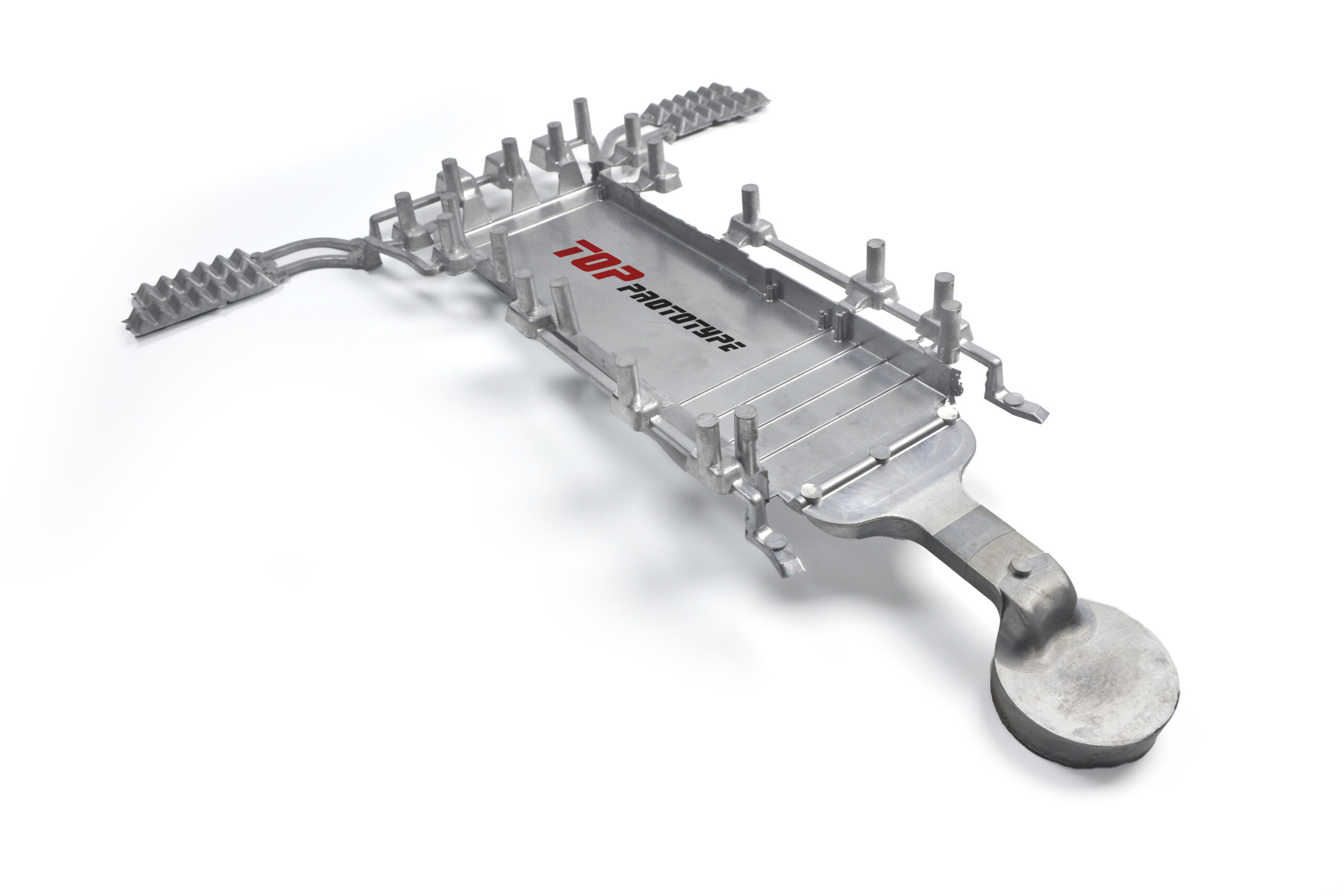

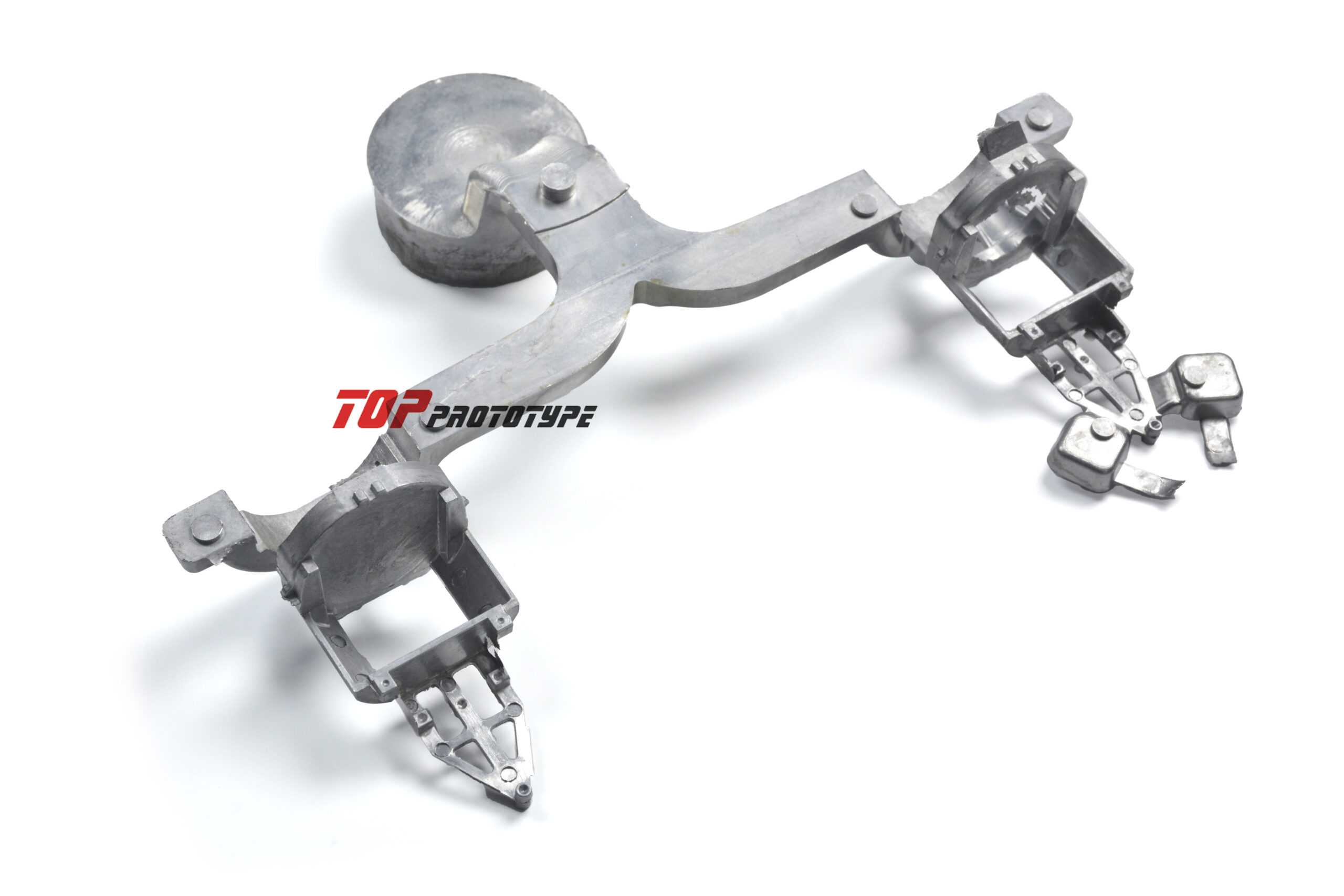

Die Casting Processing Parts Display

Within our die-casting services, we offer a wide range of materials to choose from. The material selection depends on the intended use of your products. For instance, stainless steel is commonly used in the automotive industry, where its strength and durability make it ideal for components that need to withstand high loads and impacts, while its excellent welding performance is another crucial factor.

Explore the main types of die-casting materials we provide to suit various needs. Have a specific material in mind? Let us know, and we’ll tailor our services to your requirements!

Die Casting Machining Materials

Within our die-casting services, we offer a wide range of materials to choose from. The material selection depends on the intended use of your products. For instance, stainless steel is commonly used in the automotive industry, where its strength and durability make it ideal for components that need to withstand high loads and impacts, while its excellent welding performance is another crucial factor. Explore the main types of die-casting materials we provide to suit various needs. Have a specific material in mind? Let us know, and we’ll tailor our services to your requirements!

| Materials | Description | |

|---|---|---|

| Aluminum | Aluminum has an excellent strength-to-weight ratio among these metals. This is an excellent choice for high load requirements on aircraft mounts and enclosures. Aluminum also has good ductility, stiffness, corrosion resistance and workability. Its lightweight properties make it useful in aerospace structural applications such as fuselage skins, wing ribs, wing skins, etc. |

| Copper | Copper has excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and easy to weld. |

| Stainless steel | Stainless steel is a type of mild steel whose properties are sought after in many industrial applications. Stainless steel usually contains at least 10% chromium by weight. They are the first choice for critical joints in engine and exhaust components, landing gear components and aircraft superstructures, ensuring high performance and durability. |

| Titanium | Titanium has many material properties that make it an ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. This metal also has an excellent strength-to-weight ratio. |

| Plastic | Plastic is also a very popular choice for CNC machining because of its wide selection, relatively low prices, and significantly faster machining times. We offer CNC machining services for all common plastics. |

Die Casting Processing Surface Treatment

Surface treatment is a crucial step in the die-casting process, enhancing the functionality, appearance, and durability of the final product. Common treatments include polishing, anodizing, powder coating, and plating, which improve corrosion resistance and wear protection and achieve aesthetic finishes.

At TOP Prototype, we provide customized surface die-casting treatment solutions to meet your specific design and performance needs.

| Process | Description | |

|---|---|---|

| Sandblasting | After sandblasting treatment, the surface of the parts has a matte texture. It is mainly used for visual applications and can then undergo other surface treatments. |

| Anodizing | Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects metal surfaces. Widely used in mechanical parts, precision instruments, aircraft, automobile parts, etc. |

| Electrostatic spraying | Electrostatic spraying is a coating applied as a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporating solvents, powder coatings are typically applied electrostatically and then cured under heat or UV light |

| Polishing | The polishing range spans from Ra 0.8 to Ra 0.1. The polishing technique utilizes abrasive materials to rub against the surface of the parts, leading to the surface of the parts becoming either more lustrous or less lustrous, all depending on your requirements. |

| Plating | The electroplating coating enables the reduction and deposition of metal cations by applying an electric current, which can protect the surface of the parts and prevent corrosion caused by rust and other defects. |

Why Choose Top Prototype for Custom Die Casting Services?

TOP Prototype offers exceptional die-casting services with precision tolerances as tight as ±0.05mm for standard parts and up to ±0.01mm for more demanding applications. Our die-casting processing center is capable of handling complex and intricate designs, ensuring we can manufacture parts from a variety of materials to meet your specific requirements. Top Prototype provides 24/7 engineering support with die-casting service. Our experienced team is always available to provide guidance and answer any questions throughout the project, helping you achieve the best possible results from our die-casting solutions.

High precision standard

For small batch parts, die-casting services can achieve standard tolerances of ±0.05mm. For parts with higher requirements, we can also achieve ±0.01mm

Handling complex designs

The die-casting processing center of TOP Prototype is capable of processing all kinds of complex and precise parts. No matter what materials or how difficult it is, we can manufacture parts that meet your unique needs

24/7 engineering support

TOP Prototype is equipped with experienced engineers to answer your questions during the project and always provides first-class engineering support to help you achieve the best results from the project.

FAQ

TOP Prototype support the two primary methods of die casting service; hot chamber die casting and cold chamber die casting. Hot chamber casting is typically used with lower melting point materials such as zinc and magnesium. Cold chamber casting is often used for comparatively higher melting point materials such as aluminum.

The die casting process within our service can create parts with alloys of the following elements (listed from most common to least):

Aluminum – Lightweight, high dimensional stability, good corrosion resistance and mechanical properties, high thermal and electrical conductivity, strength at elevated temperatures

Zinc – Easy to cast, high ductility, high impact strength, easily plated Magnesium – Easy to machine, excellent strength-to-weight ratio

Copper – High hardness and corrosion resistance, high mechanical properties, excellent wear resistance and dimensional stability

Lead / Tin – High density, good dimensional control, special forms of corrosion resistance

Automotive – Die casting solution is used to manufacture engine components, transmission housings, wheels, and other critical parts that require strength, precision, and lightweight properties.

Aerospace – Die-casting components, such as brackets, housings, and structural parts, are essential for the aerospace industry, which demands high strength-to-weight ratios and precise tolerances.

Electronics – Die casting plays a vital role in the production of heat sinks, enclosures, connectors, and other parts for electronic devices, offering both performance and aesthetic appeal.

Consumer Goods – Household appliances, furniture hardware, and other consumer products often use die-cast parts for their durability and smooth finishes.

Medical Devices – Die casting provides critical parts for medical equipment, including casings, connectors, and other components that must meet stringent quality and precision standards.

Industrial Equipment – Die-casting parts like pump housings, valve bodies, and structural components are widely used in the manufacturing of industrial machinery and equipment.

Die Casting Equipment

TOP Prototype implements strict quality control protocols to ensure every customer receives quality products.