Injection Molding Service

TOP Prototype offers small-batch and mass production injection molding services. These include thermosetting silicone injection molding and metal injection molding.

ISO 9001:2015 certification

The fastest mold processing is 1 week

Technical support and design guidance

- Home

- CAPABILITIES

- INJECTION MOLD

1

1 hour Instant Quotes

3

3 days Lead time

1

1 pcs MOQ

0.01mm

0.01 Tolerances

Custom injection molding service

Top prototype online injection molding service development to full-scale production tooling, we deliver custom injection molding solution designed for precision and efficiency. Our capabilities include injection mold tooling, over-molding and insert molding. With advanced facilities and an experienced team, we ensure high-quality results for every order. Send us your design files to receive a free quote and expert guidance, let us help you bring your ideas to life with cost-effective and reliable injection molding solutions.

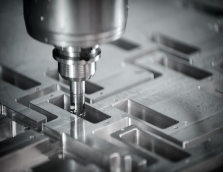

Injection Mold Tooling

Injection Mold Tooling is crucial for mass production.

It involves machining and assembling durable molds from steel or aluminum.

These molds ensure precise and repeatable part geometries for efficient manufacturing.

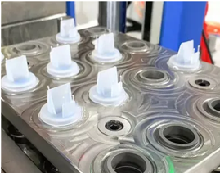

Overmolding

Over-molding is a key process in injection molding services that integrates different materials into a single part. It fuses different materials into one part, enhancing product functionality and aesthetics. It can add soft grips and multi-color designs, improving usability for a better product.

Insert Molding

Selective laser sintering (SLS) 3D is a technology where the material is heated, but not to the point of melting, to create high resolution items.

Metal powder is used for direct metal laser sintering while thermoplastic powders are used for selective laser sintering.

Injection Molding Parts Display

Top Prototype injection molding services include a wide range of injection parts for you. All of the injection molding parts are crafted with high precision, exceptional durability, and quality to meet diverse project industry needs and specific requirements. Explore the possibilities for your next project!

Injection Molding Processing Materials

The materials used in our custom injection molding services include a wide variety of plastics. Our injection molding materials are characterized by high performance, exceptional strength, and excellent impact resistance, making them ideal for a range of industries and applications. We can source thousands of materials upon request. Contact us today to discuss your specific needs!

| Materials | Description | ||

|---|---|---|---|

| ABS | High impact resistance, toughness, and rigidity. | |

| PEEK | High performance thermoplastic with excellent thermal stability. | |

| PE | Excellent strength-to-weight ratio with excellent rigidity and strength. | |

| PC | High impact strength with excellent transparency and impact resistance. | |

| PA | High strength, low friction coefficient, high wear resistance. |

Injection Molding Processing Surface Treatment

TOP Prototype surfacing finishing techniques of injection molding can either be for functional or aesthetic purposes. Each technique has requirements, such as materials, color, texture, and price. Below are the surfacing finishing technique rendered by us.

| Process | Description | |

|---|---|---|

| Painting | In Plastic Injection, painting offers many color choices and finishes, enhancing the aesthetic appeal of plastic products. It also provides protection against scratches and UV rays, increasing durability and longevity. |

| Electroplating | Electroplating deposits a metal coating via electric current. This protects the surface from corrosion caused by rust and other defects, enhancing durability and appearance. |

| Silk-Screen Printing | Silk-Screen printing is a technique that applies ink through a stencil onto the plastic surface, allowing for the creation of detailed designs and logos. |

| Texturing | t's usually done using textured molds or chemical treatments. When molten plastic is injected into the textured mold, it takes on the mold's pattern, creating a textured surface on the product. This makes it more visually appealing and provides better grip, reducing slippage risk. |

| Laser Etching | The electroplating coating enables the reduction and deposition of metal cations by applying an electric current, which can protect the surface of the parts and prevent corrosion caused by rust and other defects. |

Why Choose to working with our custom injection molding services?

Top Prototype delivers exceptional injection molding services designed to meet the demands of businesses seeking precision and efficiency. We achieve standard tolerances of ±0.05mm for small-batch parts and can reach ±0.01mm for applications requiring the highest level of accuracy. Our advanced facilities are equipped to handle even the most complex and intricate designs, ensuring your custom parts are manufactured to exact specifications, regardless of material or difficulty. With rapid prototyping capabilities and fast production turnaround, we provide reliable and scalable custom injection molding solutions that empower your business to stay ahead in a competitive market.

High precision standard

Our custom injection molding services achieve standard tolerances of ±0.05mm for small-batch parts and can meet high-precision requirements with tolerances as tight as ±0.01mm.

Handling complex designs

No matter the material or design complexity of the injection molding, we manufacture custom parts to your exact specifications with guaranteed quality.

Fast production speed

Receive a quote within 1 hour, with delivery times as fast as 3 days to efficiently meet your project needs.

FAQs

Injection molding (RIM) is a rapid injection moulding process that highly reactive plastic liquids are mixed under low pressure and then injected into a mold to react, cure, and turn into unreinforced thermoset parts.

High quality tooling with multi cavities produced in fully hardened steel should be expected to produce 1 million shots before extensive refurbishment cost. As your moulder/molder what tool life they will guarantee.

When choosing the best plastic for injection molding, the most commonly used materials are: Acrylonitrile Butadiene Styrene (ABS) Polypropylene High Impact Polystyrene High-Density Polyethylene.

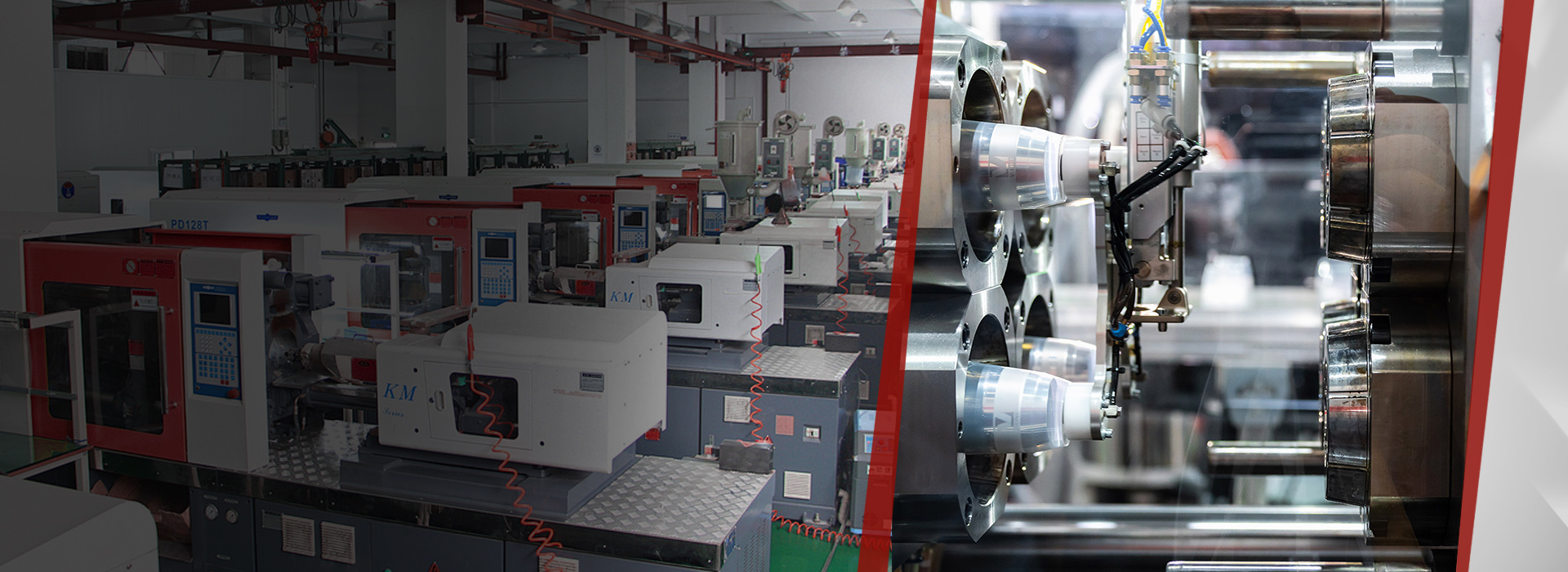

Injection Mold Equipment

TOP Prototype implements strict quality control protocols to ensure that each customer receives high-quality products in a timely manner.