Sheet Metal Fabrication Service

Sheet metal fabrication is a comprehensive cold processing method for thin metal sheets, primarily involving procedures such as shearing, punching/cutting/combining, bending, welding, riveting, assembling, and forming. It is typically used to process metal sheets with a thickness of less than 6mm, such as steel plates, aluminum sheets, and copper sheets. The basic processes of sheet metal fabrication include blanking, bending, welding, riveting, assembling, and forming. custom metal fabrications are featured lightweight, high strength, and cost-effectiveness, making them suitable for large-scale production. As a result, sheet metal fabrication solutions are widely applied across various industries, including electronics, automotive, and medical devices.

Tolerance as tight as ±0.0004 "(0.01mm)

The fastest processing parts 1 day

Mass production

- Home

- CAPABILITIES

- SHEET METAL PROCESSING

1

1 hour Instant Quotes

3

3 days Lead time

1

1 pcs MOQ

0.01mm

0.01 Tolerances

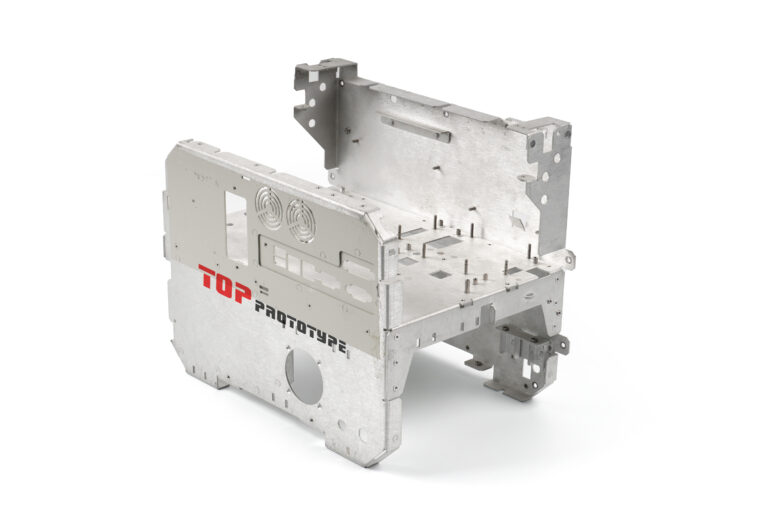

Sheet Metal Machining Parts Display

Through our sheet metal machining components and parts, you can gain deeper insights into Top Prototype’s processing capabilities and technical expertise in sheet metal fabrication services. Explore our diverse sheet metal fabrication parts to discover more about our custom design capabilities and spark your design ideas for custom sheet metal projects. If you already have specific ideas, please send your files to us, and we will provide you with expert, detailed sheet metal fabrication solutions!

Sheet Metal Fabrication Services

Sheet metal fabrication services at Top Prototype involve processes like stamping, laser cutting, bending, and plasma cutting. With a wide selection of materials and finishes, these services can meet your specifications. Each type of sheet metal fabrication has its own unique features. High efficiency, precision, and flexibility make it suitable for the needs of various industries, such as automotive, medical devices, aerospace, robotics, energy, and electronics.

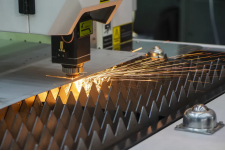

Laser cutting

Laser cutting is a sophisticated slitting

process that enables the cutting of metallic

and non-metallic raw materials of various material thicknesses.

It is a high-precision CNC thermal process that utilizes a high-

power laser beam to precisely cut, melt, or burn a material sheet.

Plasma cutting

Plasma cutting, also known as plasma arc cutting, is an efficient melting process In this process, a jet of ionized gas with temperatures exceeding 20,000°C is employed to melt and expel the material.

Stamping

Metal stamping is a category of manufacturing that uses coldforming processes to create metal parts with distinct shapes out of metal sheets or stock.

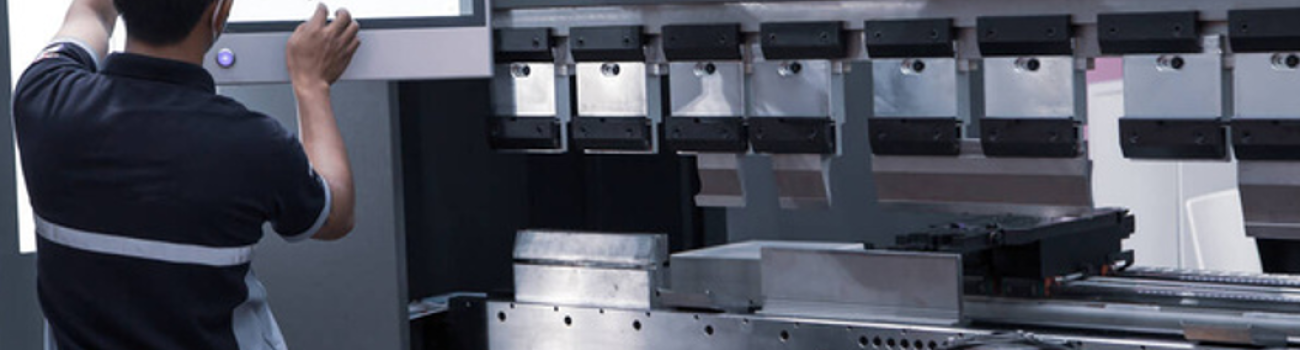

Bending

The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength, causing the material to physically deform without breaking or failing.

Sheet Metal Fabrication Materials

At Top Prototype, we offer thousands of materials for your custom sheet metal fabrication solution. Enable your designs to come to life with our precise sheet metal manufacturing techniques, flexible customization options, and rapid turnaround times.

| Materials | Description | |

|---|---|---|

| Steel | Stainless steel usually contains at least 10% chromium by weight. They are the first choice for critical joints in engine and exhaust components, landing gear components and aircraft superstructures, ensuring high performance and durability. |

| Aluminum | Aluminum has an excellent strength-to-weight ratio among these metals. This is an excellent choice for high load requirements on aircraft mounts and enclosures. Aluminum also has good ductility, stiffness, corrosion resistance and workability. Its lightweight properties make it useful in aerospace structural applications such as fuselage skins, wing ribs, wing skins, etc. |

| Copper | Copper has excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and easy to weld. |

| Alloy | Alloy refers to a material made by combining two or more metals or a metal and a non-metal. Alloys often have improved properties compared to pure metals, such as increased strength, hardness, corrosion resistance, or better electrical conductivity. They are widely used in various industries, including aerospace, automotive, construction, and electronics. |

Sheet Metal Processing Surface Treatment

TOP Prototype’s custom metal fabrication surfacing finishing techniques serve both functional and aesthetic purposes. Each sheet metal technique has specific requirements, such as materials, color, texture, and price. Below are the surfacing finishing techniques we offer.

| Process | Description | |

|---|---|---|

| Painting | This gives the sheet metal a protective coating and can also enhance its appearance. Different colors can be applied according to specific requirements. |

| Powder Coating | It provides a durable finish that is resistant to scratches, corrosion, and fading. Powder coating can offer a wide range of colors and textures. |

| Anodizing | Commonly used for aluminum sheet metal. Anodizing creates a protective oxide layer on the surface, which can improve corrosion resistance and give the metal a decorative finish. |

| Galvanizing | This process involves coating the sheet metal with zinc to protect it from rust and corrosion. Galvanized sheet metal is widely used in construction and outdoor applications. |

| Electroplating | Deposits a thin layer of metal on the surface of the sheet metal, such as chrome, nickel, or gold. Electroplating can improve appearance, corrosion resistance, and conductivity. |

Why Choose our Custom Metal Fabrication Service?

Within our sheet metal fabrication service, you have thousands of sheet metal materials, finishes, tolerance for your order, and solutions. And our sheet metal fabrication service can achieve standard tolerances of ± 0.05mm. For parts with higher requirements, we can also achieve ±0.01mm. TOP Prototype’s sheet metal machining centers are capable of machining a wide range of complex precision parts. No matter what the material, no matter how difficult, we can create a part to meet your unique needs. Also, during the entire sheet metal fabrication project, we are equipped with experienced engineers to answer your questions and always provide first-class engineering support to help you achieve the best results from the project.

High precision standard

Achieve standard tolerances of ± 0.05mm. For parts with higher requirements, we can also achieve ±0.01mm.

Handle complex designs

Easily handle all kinds of complex sheet metal fabrication parts design.

24/7 engineering support

Professional engineers and assistants support your sheet metal fabrication projects throughout the whole project and are on stand-by 24/7.

FAQ

TOP Prototype sheet metal fabrication services include cutting, punching, bending, hemming, and welding to satisfy all your needs.

The materials available for sheet metal manufacturing are aluminum, stainless steel, mild steel, copper and zinc, etc. Or you can let us know your material requirement.

The lead time of sheet metal fabrication services depends on the material, quantity, finishing, and other fabrication requirements. In most cases, it takes about 5-7 days.

Sheet Metal Processing Equipment

TOP Prototype implements strict quality control protocols to ensure that every customer receives quality products