Swiss Lathe Processing

Swiss lathe machining provides specialized tool cutting to process metal blanks into complex, slender or precise parts, which can match the parts with more stringent requirements.

More cost-effective

Higher precision

Processing parts in as fast as 1 day

- Home

- CAPABILITIES

- SWISS LATHE PROCESSING

1

1 hour Instant Quotes

3

3 days Lead time

1

1 pcs MOQ

0.01mm

0.01mm Tolerances

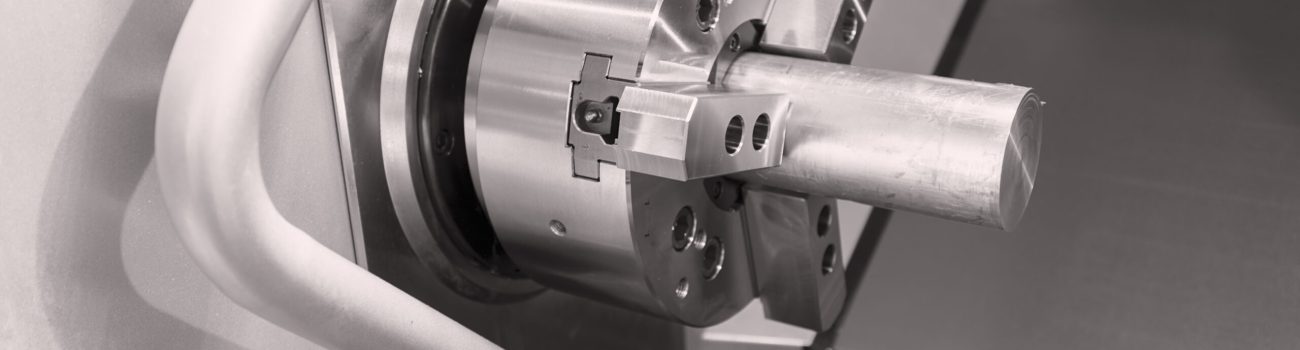

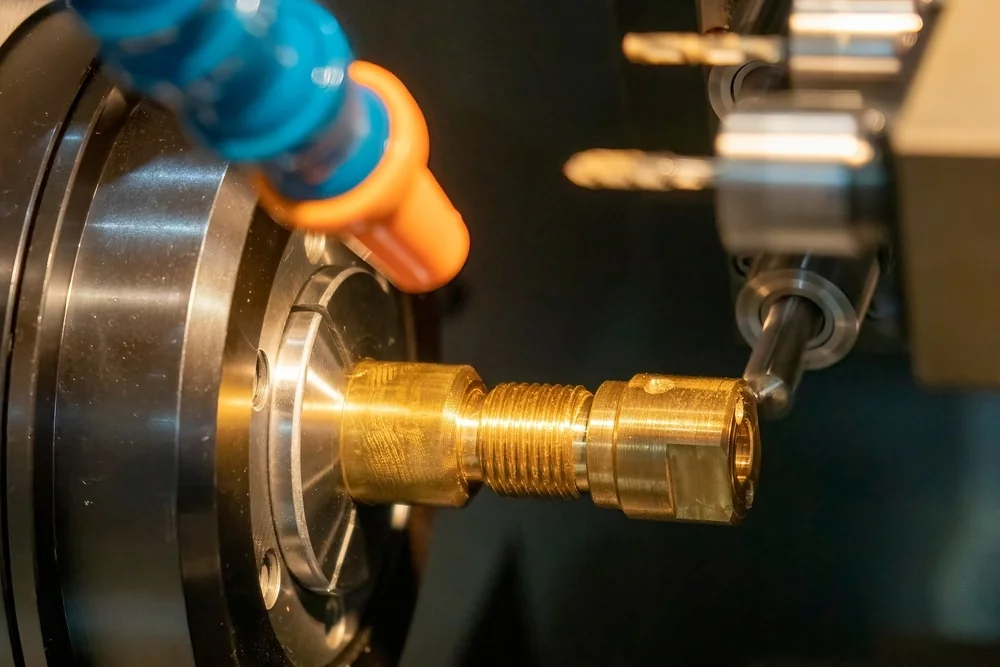

Swiss Lathe Parts Display

We warmly invite you to visit our CNC Swiss lathe machining factory, where we offer fully functional Swiss machining products. Our experienced technicians, combined with the latest advanced technologies, ensure that we deliver one of the best Swiss machining services, providing you with a professional and high-quality processing experience.

Swiss Lathe Processing Capability

The Swiss lathes of TOP Prototype adopt a dual-axis arrangement of tools. By shortening the tool exchange time between the gang tool and the opposite tool post, the processing cycle time is significantly saved. The functions of overlapping multiple tool posts and effective axis movement overlapping of thread chips are realized, reducing labor costs and defective products in the production process. Our Swiss machining services can be used to produce large quantities of precision shaft parts. The parts are mostly applied in medical equipment, optical equipment, needles, shafts, timers, aerospace components, etc. With our precise CNC Swiss lathe machining service, we ensure the highest quality and efficiency to all of our customer.

Swiss Lathe Machining Materials

We provide more than 50 types of materials for our CNC swiss screw machine services , and all of our materials are meet production standards. Our precision Swiss machining services cater to a wide range of materials, from metals to plastics. Explore our Swiss lathe machining material list and feel free to contact us to discuss your specific requirements and how we can support your business needs!

| Materials | Description | |

|---|---|---|

| Aluminum | Aluminum has an excellent strength-to-weight ratio among these metals. This is an excellent choice for high load requirements on aircraft mounts and enclosures. Aluminum also has good ductility, stiffness, corrosion resistance and workability. Its lightweight properties make it useful in aerospace structural applications such as fuselage skins, wing ribs, wing skins, etc. |

| Copper | Copper has excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and easy to weld. |

| Stainless steel | Stainless steel is a type of mild steel whose properties are sought after in many industrial applications. Stainless steel usually contains at least 10% chromium by weight. They are the first choice for critical joints in engine and exhaust components, landing gear components and aircraft superstructures, ensuring high performance and durability. |

| Titanium | Titanium has many material properties that make it an ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. This metal also has an excellent strength-to-weight ratio. |

| Plastic | Plastic is also a very popular choice for CNC machining because of its wide selection, relatively low prices, and significantly faster machining times. We offer CNC machining services for all common plastics. |

Swiss Lathe Surface Treatment

The surface treatment of CNC Swiss lathe machining can serve functional or aesthetic purposes, depending on the requirements of your project. Each Swiss machining service involves specific considerations, including material compatibility, desired color, surface texture, and budget constraints. Explore our detailed CNC Swiss screw surface processing technique options and explanations to discover how we can meet your exact needs with precision and efficiency.

| Process | Description | |

|---|---|---|

| Sandblasting | After sandblasting treatment, the surface of the parts has a matte texture. It is mainly used for visual applications and can then undergo other surface treatments. |

| Anodizing | Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects metal surfaces. Widely used in mechanical parts, precision instruments, aircraft, automobile parts, etc. |

| Electrostatic spraying | Electrostatic spraying is a coating applied as a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporating solvents, powder coatings are typically applied electrostatically and then cured under heat or UV light |

| Polishing | The polishing range spans from Ra 0.8 to Ra 0.1. The polishing technique utilizes abrasive materials to rub against the surface of the parts, leading to the surface of the parts becoming either more lustrous or less lustrous, all depending on your requirements. |

| Plating | The electroplating coating enables the reduction and deposition of metal cations by applying an electric current, which can protect the surface of the parts and prevent corrosion caused by rust and other defects. |

Why choose our Swiss Lathe Machining services?

Top prototype is known for high-precision Swiss lathe machining services, we are able to meet tight tolerance standards of ±0.05mm, suitable for most industrial parts production. For applications requiring even higher precision, our advanced CNC Swiss lathe machining equipment and techniques can achieve tolerances as fine as ±0.01mm. Our CNC Swiss screw machine services ideally for industries such as aerospace, medical devices, and high-end electronics. We also offer custom Swiss Machining Services and solutions, flexible to adjust machining processes to meet your specific needs and ensuring that the dimensions, shapes, and functions of your parts perfectly align with design specifications. Equipped with state-of-the-art Swiss lathe machining centers, our workshop enables rapid prototyping and small-batch production of parts, with turnaround times as quick as 1-3 days. Our meticulous production management ensures high-quality standards and precision at every stage, helping you save both time and costs while delivering exceptional manufacturing results. Beyond precision, our Swiss lathe machining capabilities also guarantee excellent surface finishes. Precise Swiss machining cutting techniques ensure smooth, polished surfaces that reduce friction and enhance the durability of your parts. We also offer a range of post-processing options, including plating, polishing, and shot peeing, to further improve the appearance, corrosion resistance, and mechanical performance of your components.

High precision standard

Able to deliver exceptional precision, meeting tolerance standards of ±0.05mm. Offer custom solutions achieving tolerances as tight as ±0.01mm.

High Efficiency & Productivity

Our advanced CNC Swiss lathe machining services ensure rapid prototyping and small-batch production within 1-3 days.

Surface effect

Swiss CNC machine services guarantee smooth, high-quality finishes that enhance durability and reduce friction.

Swiss Lathe Processing Applications

Swiss machining capabilities in top prototyping can be applied across a wide range of industries, including medical, aerospace, and the electronics industry. Components manufactured by Swiss lathe can be small and precise, making them ideal for applications such as dental implants, surgical instruments, and orthopedic devices. The aerospace industry often requires small, complex parts like aircraft engine components and navigation systems. The precision and accuracy of Swiss machining make it perfect for producing components that meet stringent flight requirements and can endure extreme environmental tests. In the electronics industry, microelectronics, connectors, and sensors are commonly used. Swiss CNC machines are known for their exceptional precision and reliable performance, making them ideal for meeting the diverse demands of various industries.

Medical industry

Suitable for manufacturing dental implants, surgical instruments, and orthopedic devices with high precision and reliability.

Aerospace industry

Ideal for producing complex components such as aircraft engine parts and navigation systems, meeting stringent industry standards.

Electronics industry

Perfect for crafting microelectronics, connectors, and sensors with exceptional accuracy and consistency.

FAQ

CNC Swiss machining is widely used in industries that require high precision and complex parts, such as aerospace, medical, electronics, and automotive.

CNC Swiss machining is known for its high accuracy and precision. It is capable of producing complex parts with tight tolerances, typically less than one-thousandth of an inch.

CNC Swiss machining uses various materials, including metals, plastics, and composites. Some common materials used in CNC precision machining include:

Metals: aluminum, brass, copper, stainless steel, titanium, and others

Plastics: acrylic, nylon, polycarbonate, polyethylene, PVC, and others Composites: carbon fiber, fiberglass, Kevlar, and others.

Swiss Lathe Equipment

TOP Prototype implements strict quality control protocols to ensure that customers receive the highest quality products. We have a dedicated inspection workshop, equipped with the most advanced equipment for inspection operations.