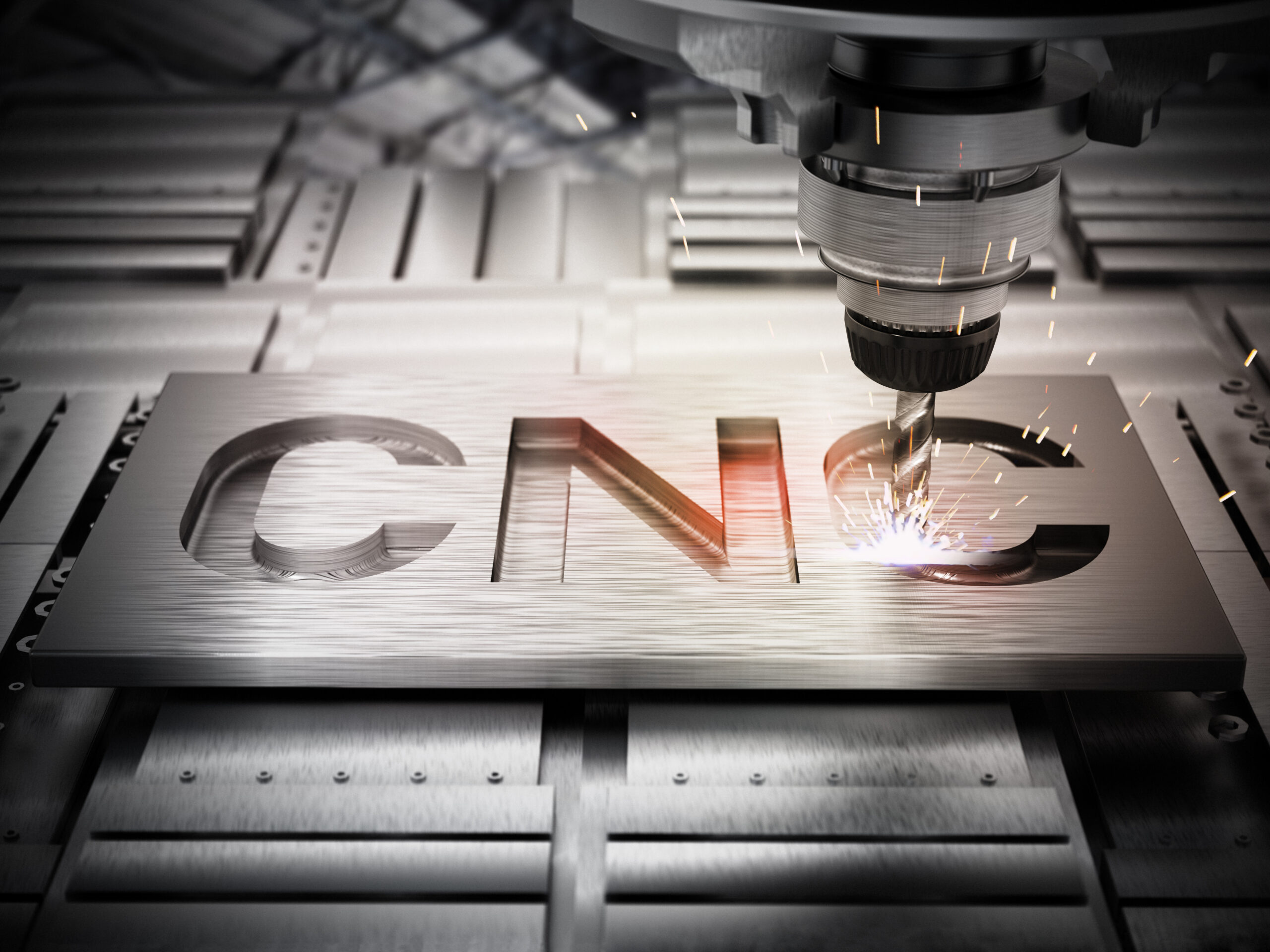

Computer Numerical Control (CNC) rapid prototyping refers to the use of CNC machining technology to create prototypes quickly and accurately from a digital design. The process involves converting 3D models into machine code, which then directs CNC equipment to cut or shape materials into physical prototypes.

CNC rapid prototyping has become a vital part of modern manufacturing and product development, significantly improving the efficiency and quality of the process. With the help of CNC, manufacturers are able to maintain an advantage over competitors, which expedites product development cycles without sacrificing quality. This technology gives a competitive edge in a field that is constantly changing by not just shortening time-to-market but also enabling ongoing design refinement. For example, in industries like automotive, aerospace, medical devices, and electronics, CNC rapid prototyping can minimize costs associated with errors in the designing phase.

Indeed, CNC rapid prototyping is essential to manufacturing. Here are seven significant advantages of this technology. Let’s take a look.

Reason 1: Precision and Accuracy

One notable feature of fast CNC machining is its extraordinary accuracy and precision. Other prototyping methods and manual processes cannot match the precise tolerances of CNC machines. CNC machines are controlled by advanced software and follow precise digital instructions to create complex parts with exact specifications. This precision is vital in industries where even the most minor dimensional errors can result in functionality issues or safety concerns. In manual machining, the operator manually controls cutting tools to shape the material, which inevitably introduces human error, inconsistency, and slower production times. Even experienced machinists may find it impossible to maintain the same level of accuracy that CNC machines achieve.

Reason 2: Quick Turnaround Time

In these fast-paced markets, speed is crucial in order to provide a quick turnaround time. By drastically cutting production time, CNC rapid prototyping enables businesses to shorten the product development cycles. CNC machines have a continuous operating cycle and can quickly and effectively produce complex prototypes. Maintaining competitiveness and acting quickly in response to market needs depend on this quick turnover. The quicker a company can produce prototypes and bring a product to market, the greater its competitive advantage.

Reason 3: Material Versatility

The material diversity of CNC rapid prototyping is one of its main advantages. CNC machines can process various materials, from metals and plastics to composites, wood, and even specialized materials like ceramics. This versatility is crucial in product development, as it allows engineers and designers to manufacture prototypes that closely replicate the final product in terms of strength, durability, and appearance.

Reason 4: Cost-Effective for Small Batches

CNC rapid prototyping is an affordable option for short production runs or one-off prototypes. Low-volume production is less viable for traditional manufacturing techniques like injection moulding because they need costly tooling. However, CNC rapid prototyping reduces costs. It is perfect for startups or businesses with low production requirements because it does not require the need for specialized tools, which makes manufacturing more viable. By eliminating the expensive tooling needs, reducing setup costs, and enabling quick design iterations, CNC rapid prototyping empowers businesses to innovate more freely while keeping production costs manageable, even for small quantities.

Reason 5: Enhanced Design Validation

Rapid prototyping with CNC is essential for enhancing designs. Before moving on with mass production, engineers are able to extensively test and assess their designs thanks to the production of highly exact prototypes. This early validation ensures that the final product fulfills its intended function and helps uncover potential flaws, lowering the risk of costly errors, which can be highly beneficial for businesses.

Reason 6: Accelerated Design Iteration

Rapid design iterations are yet another critical benefit of CNC rapid prototyping. Digital ideas may be quickly translated into tangible prototypes using CNC machines, enabling quick adjustments and advancements. In today’s competitive market, this accelerated iteration process is essential for helping businesses enhance their designs and stay ahead of the curve.

Reason 7: Collaboration and Communication

CNC rapid prototyping plays a vital role in enhancing collaboration and communication among designers, engineers, and stakeholders by enabling fast manufacturing of physical prototypes. CNC rapid prototypes make sure that everyone is on the same page by offering concrete representations. By streamlining the development process and preventing misunderstandings, this enhanced communication makes sure that the finished product meets everyone’s expectations. The ability to quickly produce accurate, tangible samples also helps bridge the gap between concept and reality, fostering better feedback loops and decision-making.

TOP Prototype’s CNC Technique

TOP Prototype’s CNC machining service realizes the combination of accuracy and speed in the creation of products. Our top-notch CNC machines are built to produce with excellent efficiency and quick turnaround times. Our precision machining services offer the accuracy and material variety you need to rapidly and affordably achieve your designs, whether you need a single prototype or a small production run. The state-of-the-art CNC technology and our extensive knowledge of creating prototypes form a solid foundation for ensuring extremely high quality and matching all of your requirements.

Besides, we will meticulously analyze your project requirements and provide tailored, practical design suggestions that not only improve the aesthetic appeal but also optimize functionality and efficiency. We will also strive to bridge the often-widened gap between the initial part design and the rigorous testing phase of the final product. This inspection ensures that any potential design flaws or issues are identified and addressed early on in the development cycle, significantly reducing the risk of costly reworks and delays.

Furthermore, we prioritize timely delivery, recognizing that time is of the essence in a fast-paced business environment. By implementing efficient logistics systems and maintaining close communication with our supply chain partners, we will ensure that the finished parts are promptly dispatched and delivered to you without delay.

Conclusion

At TOP Prototype, we specialize in quickly turning design concepts into tangible, functional prototypes. With years of industry know-how, our skilled and professional team utilizes the latest technologies and techniques to streamline the prototyping process. We ensure timely delivery to prevent disruptions to clients’ schedules, fostering trust and reliability.

If you are looking for a prototype service, please visit our TOP Prototype’s official website to explore more about CNC rapid prototyping and the benefits that a turned parts manufacturer could bring to your business. If you want to have a deeper conversation with our experts, give us a call or fill out one of our contact forms with your information.