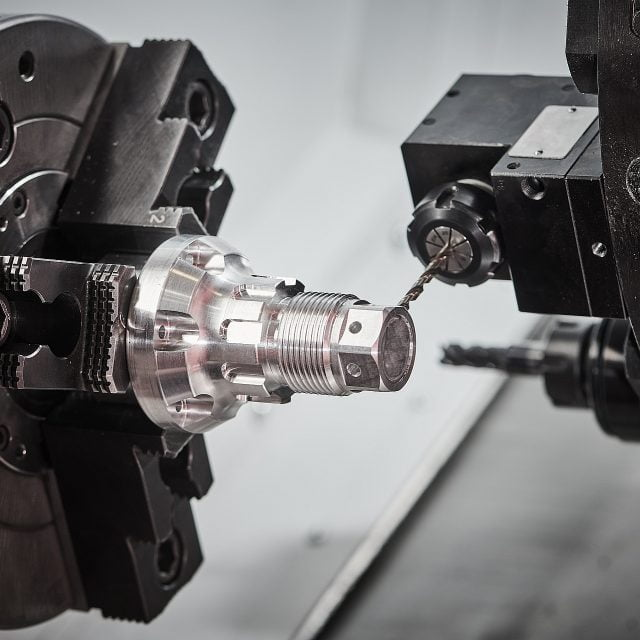

TOP Prototype CNC Drilling: Precision and Efficiency in Modern Manufacturing

In the realm of modern manufacturing, Computer Numerical Control (CNC) drilling has emerged as a crucial process that combines precision, speed, and versatility. This advanced machining technique plays a vital role in various industries, from aerospace and automotive to electronics and medical devices. In this article, we will explore the world of CNC drilling, delving into its principles, applications, advantages, and future prospects.

I. Introduction to CNC Drilling

CNC drilling is a machining process that uses computer-controlled drills to create holes in a workpiece. The process is highly automated, allowing for precise and repeatable results.

The CNC drilling machine is programmed with specific instructions that determine the location, size, and depth of the holes to be drilled. This programming can be done using specialized software or by manually entering commands into the machine’s control panel.

The basic principle of CNC drilling is similar to that of traditional drilling. A drill bit is rotated at high speed and pressed against the workpiece to remove material and create a hole.

However, in CNC drilling, the movement of the drill bit is controlled by a computer, which ensures accuracy and consistency.

The computer can also control other parameters such as feed rate, spindle speed, and coolant flow, further enhancing the quality and efficiency of the drilling process.

II. Applications of CNC Drilling

Aerospace Industry

In the aerospace industry, precision and reliability are of utmost importance. CNC drilling is widely used to create holes in aircraft components such as wings, fuselages, and engine parts. These holes are used for assembly, fastening, and ventilation purposes. The high precision and repeatability of CNC drilling ensure that the components fit together perfectly and function properly under extreme conditions.

Automotive Industry

The automotive industry also relies on CNC drilling for the production of various parts. Engine blocks, transmission cases, and suspension components often require precise holes for bolts, screws, and other fasteners. CNC drilling can quickly and accurately create these holes, improving production efficiency and reducing costs.

Electronics Industry

In the electronics industry, CNC drilling is used to create holes in printed circuit boards (PCBs). These holes are used for mounting components and providing electrical connections. The small size and high density of PCBs require extremely precise drilling, which can only be achieved with CNC drilling machines.

Medical Device Industry

The medical device industry demands high precision and quality in the production of surgical instruments, implants, and other devices. CNC drilling is used to create holes in these devices for assembly, fastening, and fluid flow. The accuracy and cleanliness of CNC drilling ensure that the devices are safe and reliable for use in medical procedures.

III. Advantages of CNC Drilling

1.Precision and Accuracy One of the main advantages of CNC drilling is its high level of precision and accuracy. The computer-controlled movement of the drill bit ensures that the holes are drilled exactly where they are supposed to be, with tight tolerances. This precision is essential for applications where even the slightest deviation can cause problems, such as in aerospace and medical devices.

2.Repeatability CNC drilling machines can produce identical holes over and over again, ensuring consistent quality throughout a production run. This repeatability is crucial for mass production, where thousands or even millions of parts need to be produced with the same specifications.

3.Versatility CNC drilling machines can handle a wide variety of workpieces and materials, from soft plastics to hard metals. They can also drill holes of different sizes and depths, making them highly versatile. This versatility allows manufacturers to use a single machine for multiple applications, reducing equipment costs and increasing productivity.

4.Speed and Efficiency CNC drilling is a highly efficient process, capable of drilling multiple holes in a short amount of time. The computer-controlled movement of the drill bit allows for rapid positioning and drilling, reducing production time and increasing output. Additionally, CNC drilling machines can be programmed to optimize the drilling process, further improving efficiency.

5.Automation CNC drilling is a highly automated process, reducing the need for manual labor and increasing safety. The machine can be programmed to run continuously, with minimal operator intervention. This automation not only improves productivity but also reduces the risk of human error.

IV. Future Prospects of CNC Drilling

As technology continues to advance, the future of CNC drilling looks promising. Here are some of the trends and developments that are likely to shape the future of this machining process:

Increased Automation The trend towards increased automation in manufacturing is expected to continue, with CNC drilling machines becoming even more autonomous. Advanced sensors and machine learning algorithms will enable the machines to detect and correct errors in real-time, further improving precision and efficiency.

Integration with Other Technologies CNC drilling is likely to be integrated with other advanced manufacturing technologies such as 3D printing and additive manufacturing. This integration will allow for the production of complex parts with integrated features, reducing assembly time and costs.

Improved Materials and Tooling The development of new materials and tooling will continue to enhance the performance of CNC drilling. Advanced cutting tools and coatings will improve tool life and reduce wear, while new materials will offer better strength, durability, and heat resistance.

Industry 4.0 and Smart Manufacturing The concept of Industry 4.0 and smart manufacturing is expected to have a significant impact on CNC drilling. Connected machines, analysis of real-time data, and predictive maintenance will enable manufacturers to optimize their production processes and improve overall efficiency.

V. Conclusion

CNC drilling is a crucial machining process that offers precision, efficiency, and versatility in modern manufacturing. At TOP Prototype, we understand the significance of this process. Our company has been at the forefront of providing high-quality CNC drilling services. Its applications span across various industries, from aerospace and automotive to electronics and medical devices.

TOP Prototype has been actively involved in serving clients from these diverse sectors. The advantages of CNC drilling, such as precision, repeatability, versatility, speed, and automation, make it an essential tool for manufacturers looking to improve their production processes and competitiveness.

TOP Prototype is committed to leveraging these advantages to offer the best solutions to our customers. As technology continues to advance, the future of CNC drilling looks bright, with increased automation, integration with other technologies, improved materials and tooling, and the adoption of Industry 4.0 and smart manufacturing concepts.

TOP Prototype is constantly evolving to stay ahead in this dynamic field and continue to deliver top-notch CNC drilling services.