Mastering CNC Milling: TOP Prototype’s Expertise in

The Significance of CNC Milling in Modern Industry

CNC milling stands as a cornerstone in the manufacturing landscape. It has revolutionized the way complex parts are fabricated. In this era of advanced technology, TOP Prototype has emerged as a key player in harnessing the full potential of CNC milling. For example, in a typical production run at TOP Prototype, a CNC milling machine can remove up to 50 cubic centimeters of material per minute when working on aluminum workpieces.

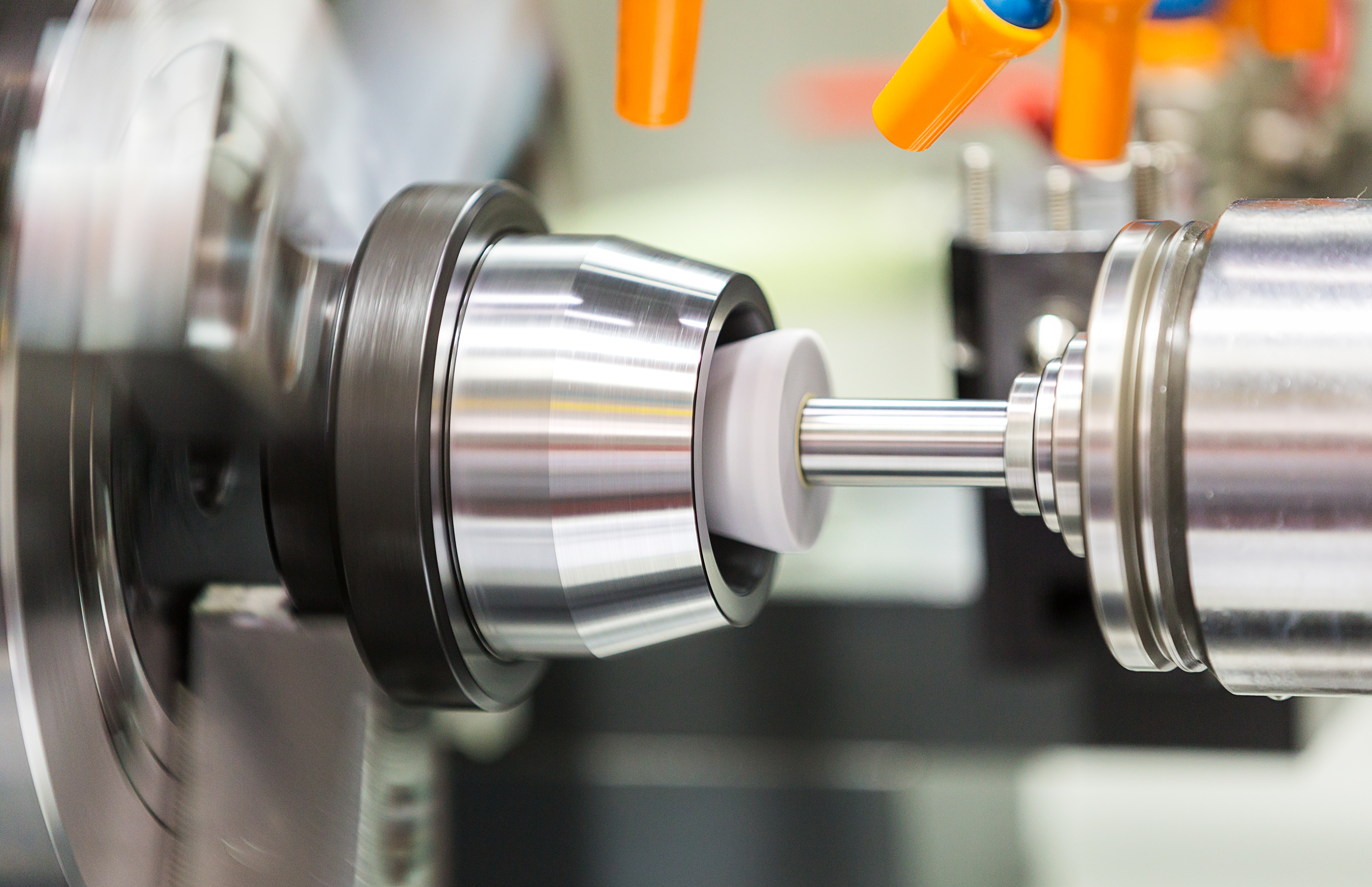

TOP Prototype’s CNC Milling Process Unveiled

Initiating the Process: CAD Models

The journey of CNC milling at TOP Prototype commences with intricate 3D CAD models. These digital blueprints serve as the guiding force for the entire manufacturing process. Consider a component with dimensions of 300mm in length, 150mm in width, and 40mm in height. The milling machine at TOP Prototype can have a positioning accuracy of ±0.003mm, ensuring the final part closely matches the CAD design.

The Arsenal of Cutting Tools:

The cutting tools, ranging from delicate 0.1mm micro – tools for fine detailing to robust 20mm cutters for efficient material removal, are the workhorses. They are precisely controlled by the CNC system. The spindle speed can vary from 500 RPM for large – diameter tools to an astonishing 30,000 RPM for the smallest tools, enabling different cutting rates and surface finishes.

Precision Standards at TOP Prototype:

Want to know more about CNC milling of us?

TOP Prototype is renowned for its unwavering commitment to precision. In high – precision optical components, they can maintain tolerances as minuscule as ±0.005mm. This level of accuracy is crucial for the flawless functioning of end products. The repeatability of the CNC milling process at TOP Prototype is within ±0.002mm, ensuring consistent quality across multiple parts.

Impact on Critical Industries:

Such precision has a profound impact on industries like aerospace. A single faulty component due to lack of precision can have catastrophic consequences. TOP Prototype ensures that every part meets the most stringent quality benchmarks. In a recent aerospace project, they achieved a dimensional accuracy of ±0.01mm for critical engine components.

Material Diversity in TOP Prototype’s CNC Milling

From Plastics to Exotic Alloys

The company’s CNC milling capabilities encompass a vast spectrum of materials. From common plastics such as polycarbonate, where a batch of 500 parts might be produced in a single run with a feed rate of 100mm per minute, to exotic alloys like Inconel. When milling Inconel, the cutting speed is typically around 30 meters per minute.

Properties and Applications

Inconel parts, with their exceptional heat resistance and strength, are used in extreme temperature environments. For example, in gas turbine components where temperatures can soar above 1000°C. The depth of cut when working on Inconel can range from 0.5mm to 2mm depending on the specific requirements.

CNC Milling in Diverse Industrial Applications

Medical Marvels

In the medical field, TOP Prototype manufactures implants. A hip implant might have a complex surface finish with a roughness average (Ra) of less than 0.2 micrometers. The dimensions are critical for a perfect fit within the human body. The milling machine can perform up to 10 passes to achieve the desired surface quality.

Automotive Advancements

For the automotive industry, engine components are fabricated. A piston with a diameter of 80mm and specific piston ring grooves is machined with high accuracy to enhance engine performance. The cutting forces during the milling of the piston can range from 50N to 200N.

Enhancing Efficiency and Productivity

High – Speed Machining

TOP Prototype‘s CNC machines are capable of operating at spindle speeds exceeding 25,000 RPM. This high – speed milling significantly reduces production time. In a production run of small – sized gears, the cycle time can be reduced by up to 40% compared to traditional machining methods.

Batch Production Benefits

In a batch production of 300 similar parts, the optimized machining process leads to substantial savings in time and resources compared to traditional manufacturing methods. The average setup time for a batch of parts at TOP Prototype is only 30 minutes.

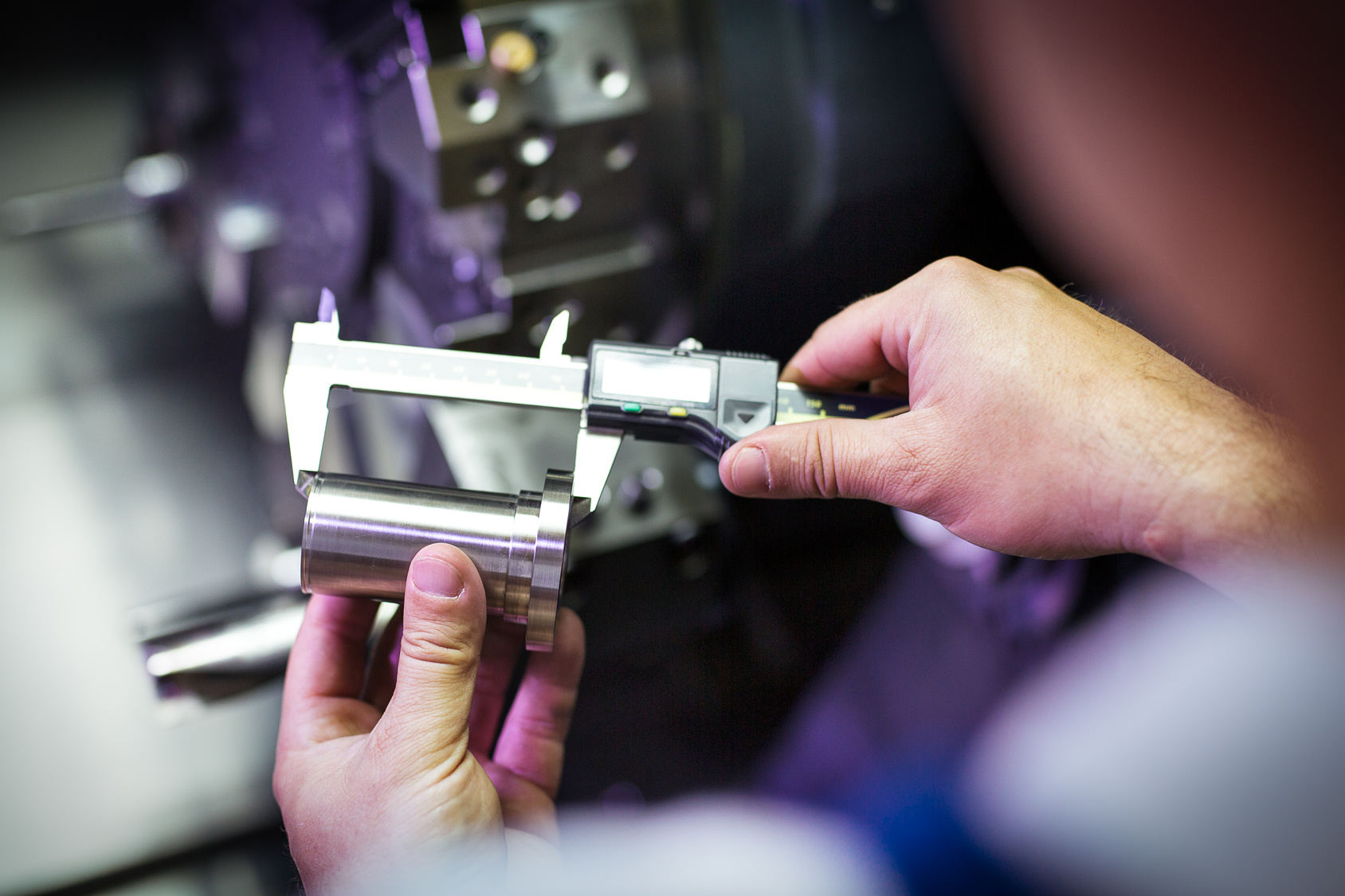

Rigorous Quality Assurance Mechanisms

Advanced Inspection Tools

Each part undergoes a comprehensive quality check using state – of – the – art metrology equipment. Optical profilometers can measure surface roughness with a resolution of 0.01 micrometers. The coordinate measuring machine (CMM) at TOP Prototype can detect dimensional deviations as small as 0.005mm.

Ensuring Consistency

This meticulous inspection ensures that every part, regardless of the batch size, adheres to the exact specifications, guaranteeing consistency and reliability. The rejection rate for parts at TOP Prototype is less than 1%.

Customization: TOP Prototype’s Edge

Tailoring to Unique Requirements

TOP Prototype excels in providing customized solutions. Whether it’s a unique aerospace bracket with a specific load – bearing design or a custom medical device component. The company can handle up to 100 unique part designs in a single production cycle.

Prototyping for Innovation

They offer rapid prototyping services. A new design for a consumer electronics casing can be prototyped within a few days, enabling quick design iterations. The average lead time for a simple prototype is 2 days.

Sustainable Manufacturing Practices

Waste Reduction Initiatives

TOP Prototype is dedicated to sustainable manufacturing. They recycle a significant portion of the metal shavings generated during milling. For every ton of material processed, around 300 kilograms of shavings are recycled. This recycling process saves approximately 50% of the raw material cost.

Energy Efficiency

The company also focuses on energy – efficient machining processes. By optimizing cutting parameters, they reduce energy consumption without sacrificing quality or productivity. The energy consumption per part can be reduced by up to 20% compared to standard machining practices.

Conclusion:

The Future of CNC Milling with TOP Prototype:

TOP Prototype’s mastery of CNC milling continues to shape the future of manufacturing. With a focus on precision, material diversity, application versatility, efficiency, quality, customization, and sustainability, they are setting new standards in the industry.