The Significance of CNC Machined Parts in Electronic Components

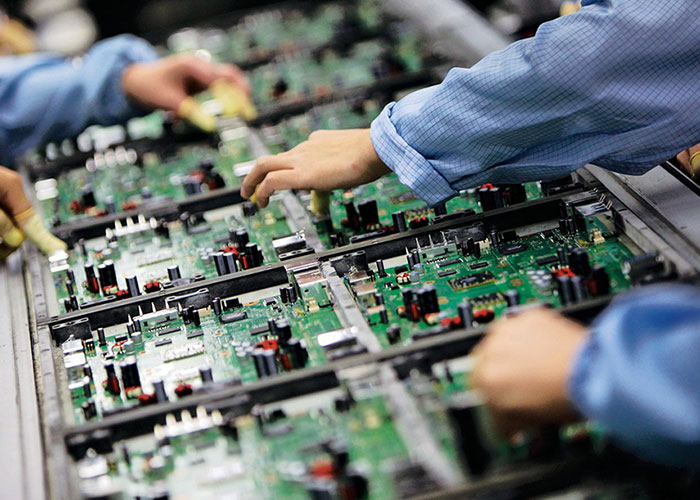

In the modern world of technology, electronic components play a crucial role in powering a vast array of devices, from smartphones and laptops to complex industrial machinery. At the heart of the production of these high-tech gadgets lies the precision manufacturing of components, and one of the most reliable and accurate methods is CNC machining. This article explores the importance of CNC machined parts in electronic components and how companies like TOP Prototype have made a significant impact in this field.

The Precision Required in Electronic Components

Electronic components need to be manufactured with utmost precision to ensure proper functionality and compatibility within a device. Even the slightest deviation in size or shape can lead to performance issues, reduced efficiency, or even complete failure of the electronic device. For example, in a microchip, the connections and circuitry are extremely intricate, and the components that support and interact with it must have precise dimensions to fit perfectly and enable seamless electrical conduction.

CNC machining offers a level of precision that is hard to match by other manufacturing methods. It uses computer-controlled processes to remove material from a workpiece with incredible accuracy, down to micrometer levels in many cases. This level of precision allows for the production of components that meet the strict tolerances required in the electronics industry. Whether it’s a tiny connector pin or a complex housing for an electronic module, CNC machining can ensure that each part is manufactured to exact specifications.

The Role of CNC Machined Parts in Electronic Components

Enhanced Performance

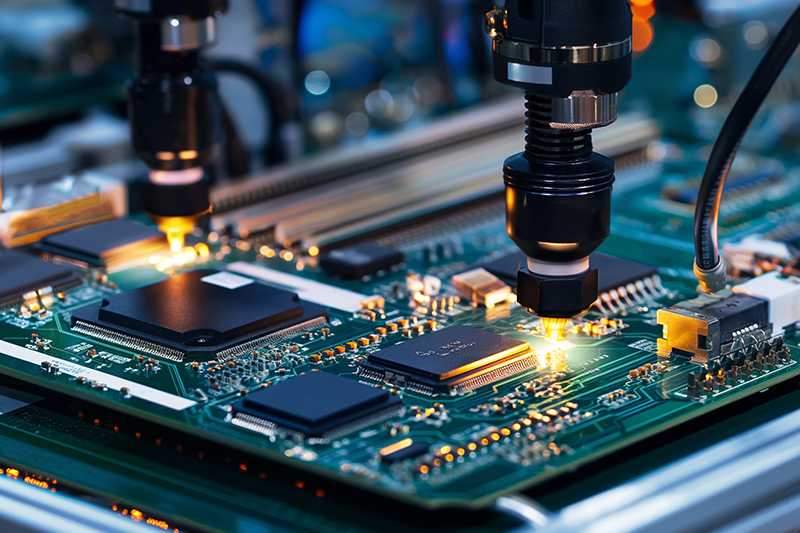

CNC machined parts contribute significantly to the overall performance of electronic components. Their precise dimensions and smooth surfaces ensure optimal electrical connections and heat dissipation. For instance, a heat sink made through CNC machining can efficiently dissipate heat generated by an electronic component, preventing overheating and ensuring the component operates at its best performance level. The accurate machining also reduces signal interference and improves the transmission of electrical signals, leading to faster processing speeds and more reliable data transfer in electronic devices.

Durability and Reliability

In the electronics industry, durability and reliability are of utmost importance. Electronic devices are expected to function flawlessly over an extended period, and the components within them need to withstand various environmental conditions and usage stresses. CNC machined parts are known for their high quality and consistency, which translate into greater durability and reliability. The parts are manufactured with tight tolerances, ensuring a perfect fit and reducing the risk of wear and tear due to loose connections or misalignments.

This is especially crucial in applications such as aerospace and automotive electronics, where the failure of a single component can have serious consequences. TOP Prototype, a leading company in the field, specializes in producing high-quality CNC machined parts for electronic components. Their strict quality control processes and advanced machining techniques ensure that each part meets the highest standards of durability and reliability, giving customers confidence in the performance of their electronic devices.

Design Flexibility

Another advantage of CNC machining in the production of electronic components is the design flexibility it offers. With the ability to work with a wide range of materials, including metals, plastics, and composites, manufacturers can create complex and customized designs to meet the specific requirements of different electronic applications. Whether it’s a unique shape for a custom electronic enclosure or a specialized internal component with intricate geometries, CNC machining can bring the design to life. This design flexibility allows for innovation in the electronics industry, enabling the development of new and improved products with enhanced features and functionality.

The Impact of TOP Prototype in the Field

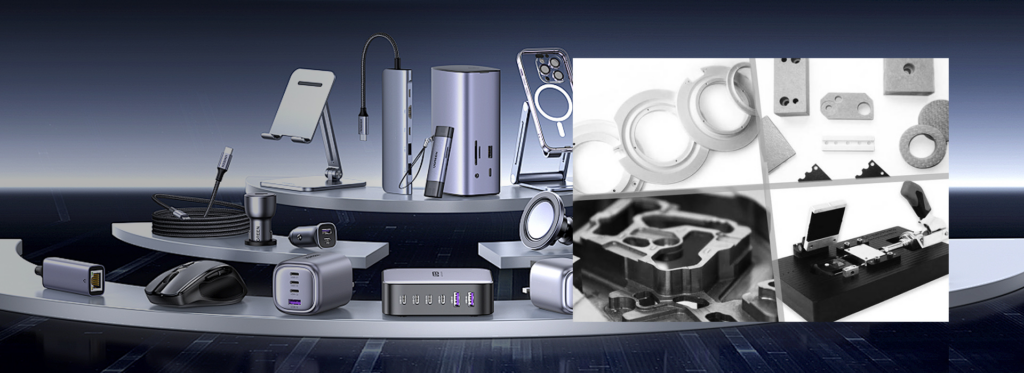

TOP Prototype has established itself as a key player in the production of CNC machined parts for electronic components. The company’s commitment to quality, precision, and innovation has made it a preferred choice for many businesses in the electronics industry.

State-of-the-Art Facilities and Technology

TOP Prototype invests heavily in state-of-the-art CNC machining equipment and technology. Their advanced machines are capable of achieving high levels of precision and efficiency, allowing for the production of complex electronic components with short lead times. The company also employs the latest software and programming techniques to optimize the machining processes, ensuring consistent quality and accurate reproduction of designs.

Quality Assurance

Quality is at the core of TOP Prototype’s operations. They have a comprehensive quality assurance system in place, which includes strict inspection procedures at every stage of the manufacturing process. From raw material selection to final product inspection, each CNC machined part is carefully examined to ensure it meets the required specifications and quality standards. This dedication to quality has earned TOP Prototype a reputation for providing reliable and high-performance CNC machined parts for electronic components, helping its customers to reduce product failures and improve overall product quality.

Customization and Collaboration

TOP Prototype understands the unique needs of its customers in the electronics industry and offers extensive customization services. They work closely with clients to understand their specific requirements and design bespoke CNC machined parts that fit perfectly into their electronic products. The company’s experienced engineering team provides valuable technical support and advice, collaborating with customers to optimize the design and manufacturing process for maximum performance and cost-effectiveness. This customer-centric approach has led to long-term partnerships with many leading electronics companies, further strengthening TOP Prototype’s position in the market.

Conclusion

In conclusion, CNC machined parts play a vital role in the production of electronic components, providing the precision, performance, durability, and design flexibility required in the modern electronics industry. Companies like TOP Prototype have made significant contributions to this field by leveraging advanced technology, ensuring high quality, and offering customization services. As the electronics industry continues to evolve and demand more advanced and reliable components, the importance of CNC machining in electronic component manufacturing will only continue to grow, and companies like TOP Prototype will be at the forefront of meeting these demands.