The consumer electronics industry has witnessed considerable growth in recent years, which can be attributed to advancements in electronic technologies such as televisions, computers, digital cameras, laptops, and other devices. The demand for such devices has also increased the demand for sheet metal fabrication.

In this article, we will provide information on sheet metal fabrication in the electronics industry and why the electronics industry requires precision manufacturing.

We will also focus on the key processes and commonly used sheet metals in the electronics industry.

The Demand for Precision Metal Fabrication in the Electronics Industry

The electronics industry is evolving rapidly. To continue producing better electronic components, the industry has the following demands for precision metal fabrication.

Miniaturization of Electronic Products

Miniaturization means manufacturing increasingly smaller electronic products without compromising efficiency or computing power. Today’s consumer demands pursue smaller and more refined electronic products that consume less energy. Without precision metal fabrication, it would be difficult to meet these demands.

By manufacturing precision thin sheets, manufacturers can utilize processes, machines, and advanced materials to manufacture miniature electronic products and integrate more functions in integrated circuits, thereby reducing the manufacturing cost of electronic products.

The Importance of Durability and Precision

Durability is an essential quality that electronic products must possess. The durability and precision of a product often depend on its material composition. Therefore, the use of sustainable materials often results in sustainable products, and vice versa.

Greater Customizability

Another important reason for sheet metal fabrication in the electronics industry is the demand for customized products. With sheet metal fabrication, customization becomes easier. For example, manufacturers can now specify the size and shape of the electronic enclosure and the metal used in the manufacturing process. Manufacturers can also create user interfaces on the enclosure and cut fans, switches, connectors, LED panels, and cables.

Common Applications in the Electronics Industry

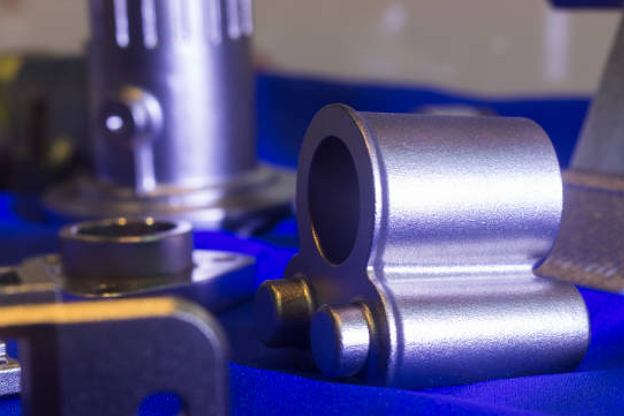

Electronic Sheet Metal Fabrication Boxes

Many devices rely on the functionality and aesthetics of sheet metal components. These components are crucial to the overall performance of these devices.

Electronic Enclosures (PCBs, Hard Drives, etc.)

Sheet metal enclosures are essential for computer equipment as they are protective containers for internal components. These enclosures protect the fragile internals from damage, dust, and moisture.

It also protects the end user from electric shock while protecting the internal components from environmental forces. Due to these enclosures, these devices are durable, making them robust enough for frequent use.

Heat Sinks and Thermal Solutions

When electronic devices operate, they often generate heat. However, the heat generated during the operation of electronic devices can negatively affect their performance and lifespan. To maintain the ideal operating temperature and avoid overheating, sheet metal heat sinks effectively dissipate heat.

Shielding Components and Preventing Radio Frequency Interference

Electromagnetic interference (EMI) and radio frequency interference (RFI) can damage electronic devices in our related world. By properly protecting these interference radiation sheet metal components, the reliability of the devices is enhanced.

Stainless steel is corrosion-resistant and is the most commonly used for brackets and connector plates. You can also use coated or plated sheet metal components.

TOP Prototype Provides Advanced Sheet Metal Processing for the Electronics Industry

TOP Prototype is a leader in the sheet metal fabrication industry, committed to part accuracy and precision. With our advanced machines and technologies, coupled with an excellent professional team with expertise in electronics manufacturing, we can provide your products for you at any time.

We understand the value of time, so we have one of the fastest turnaround times in the industry. No matter what your production scale is, whether it’s prototypes, small batch or large batch production, we can cover it.

We offer the highest quality, so we have strict quality control measures and quality assurance processes to ensure that your electronic sheet metal complies with industry quality standards.

Conclusion

Sheet metal fabrication is an important topic in the electronics industry because sheet metals are the cornerstone of modern electronics. They significantly enhance the functionality, durability, and aesthetics of modern products. These components perform essential functions, including supporting structural resilience, coordinating effective heat dissipation, and preventing electromagnetic and radio frequency interference.