The Power of TOP Prototype Powder Coating

Powder coating by TOP Prototype is a revolutionary finishing process that has gained significant popularity in various industries due to its numerous advantages and unique characteristics. In this article, we will explore the concept, working principle, history, and advantages of powder coating offered by TOP Prototype.

I. Concept of Powder Coating

Powder coating is a type of dry finishing process in which a powdered resin is applied to a surface and then cured to form a protective and decorative coating.

The powder is typically made up of a combination of resins, pigments, fillers, and additives. Unlike traditional liquid coatings, powder coating does not contain solvents, which makes it an environmentally friendly option.

II. Working Principle of Powder Coating

The powder coating process involves several steps:

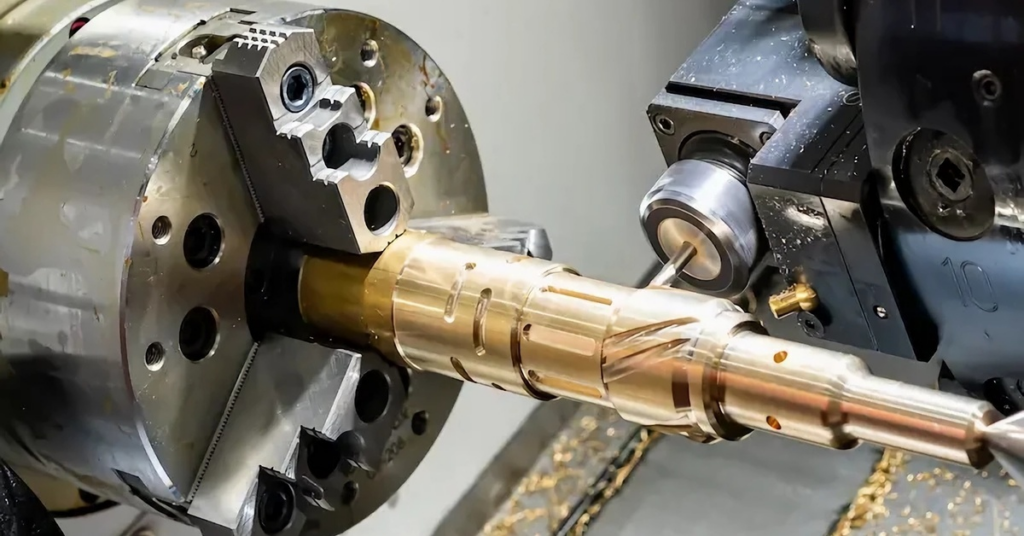

1.Surface Preparation: The surface to be coated is first cleaned and prepared to ensure proper adhesion. This may involve degreasing, sandblasting, or other pretreatment methods.

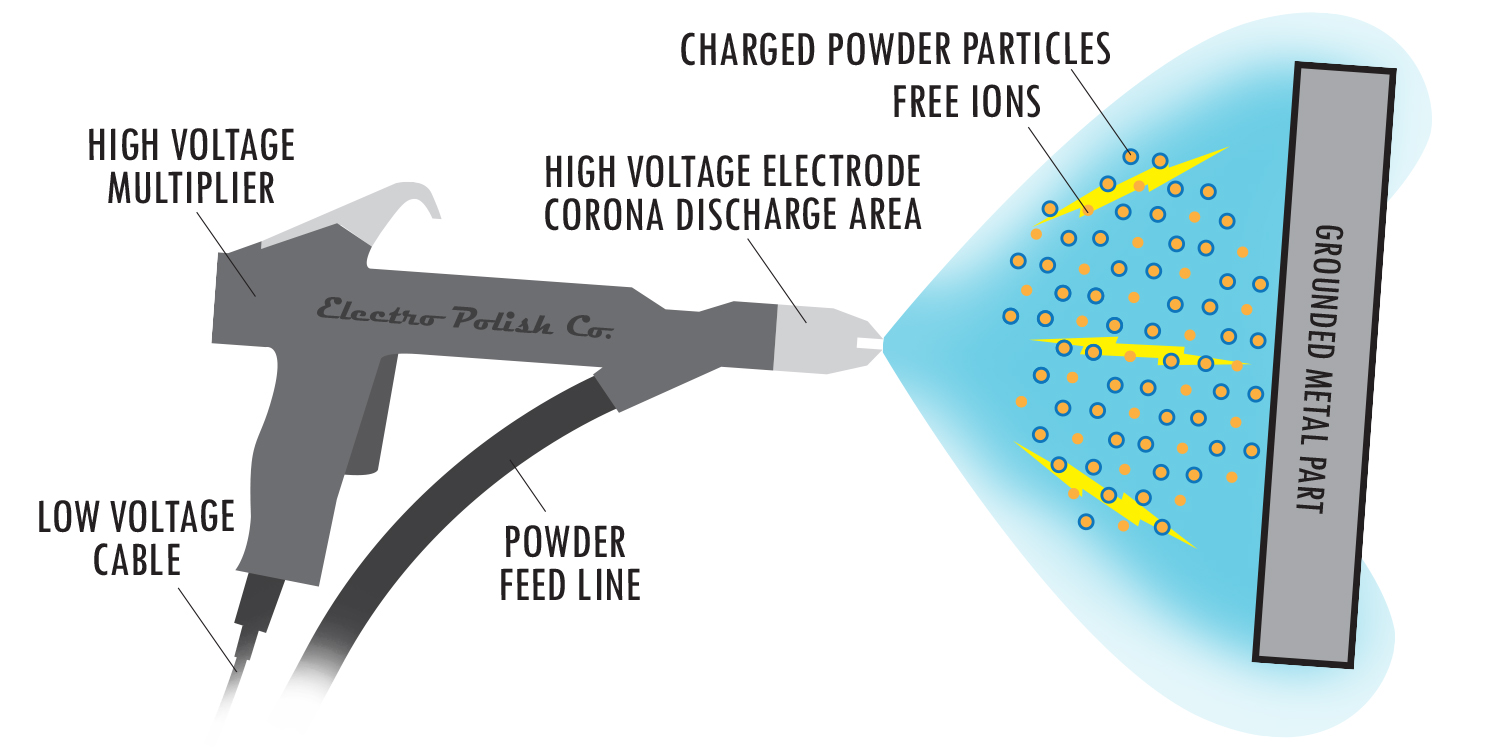

2.Powder Application: The powder is applied to the surface using one of several methods, including electrostatic spraying, fluidized bed coating, or electrostatic fluidized bed coating. In electrostatic spraying, the powder is charged with an electrical charge and then sprayed onto

the grounded surface. The electrical charge causes the powder to adhere to the surface.

3. Curing: After the powder is applied, the coated object is heated to a specific temperature to cure the powder. The heat causes the resin in the powder to melt and flow, forming a smooth and continuous coating. The curing process also crosslinks the resin, making the coating more durable and resistant to wear and tear.

III. History of Powder Coating

The development of powder coating can be traced back to the 1940s and 1950s. During this time, researchers were looking for alternative finishing methods that were more environmentally friendly than traditional liquid coatings.

In 1945, Dr. Erwin Gemmer of the United States Patent Office patented a process for applying a powder coating using electrostatic spraying. However, it was not until the 1960s that powder coating began to gain commercial acceptance.

In the 1970s and 1980s, advances in powder coating technology led to improved performance and a wider range of applications. Today, powder coating is used in a variety of industries, including automotive, appliance, furniture, and architecture.

IV. Advantages of TOP Prototype Powder Coating

1.Environmental Friendliness: One of the main advantages of powder coating is its environmental friendliness. Since powder coatings do not contain solvents, they do not emit volatile organic compounds (VOCs) into the atmosphere. This makes powder coating a more sustainable option than traditional liquid coatings.

2.Durability: Powder coatings are extremely durable and can withstand harsh environmental conditions. They are resistant to abrasion, corrosion, fading, and chipping, making them ideal for applications where long-term protection is required.

3.High-Quality Finish: Powder coatings provide a high-quality finish that is smooth, uniform, and free of defects. The coatings can be customized to match a wide range of colors and finishes, including gloss, matte, and textured.

4.Cost-Effective: Powder coating can be a cost-effective option compared to traditional liquid coatings. Since the powder can be reused and there is less waste, the overall cost of the coating process can be lower. Additionally, the durability of powder coatings means that they require less maintenance and replacement over time.

5.Efficiency: The powder coating process is highly efficient and can be completed quickly. The powder can be applied in a single coat, which reduces the time and labor required for the coating process. Additionally, the curing process is relatively fast, allowing for a quick turnaround time.

V. Applications of Powder Coating

Powder coating is used in a wide range of applications, including:

Automotive Industry: Powder coating is commonly used in the automotive industry to coat parts such as wheels, bumpers, and trim. The coatings provide a durable and attractive finish that can withstand the rigors of daily use.

Appliance Industry: Powder coating is used to coat appliances such as refrigerators, washing machines, and dryers. The coatings provide a scratch-resistant and corrosion-resistant finish that can enhance the appearance and durability of the appliances.

Furniture Industry: Powder coating is used to coat furniture such as metal chairs, tables, and shelves. The coatings provide a durable and attractive finish that can withstand the wear and tear of daily use.

Architecture: Powder coating is used to coat architectural components such as metal siding, roofing, and fencing. The coatings provide a durable and attractive finish that can withstand the elements.

VI. Conclusion

In conclusion, powder coating by TOP Prototype is a highly effective and environmentally friendly finishing process that offers numerous advantages over traditional liquid coatings.

With its durability, high-quality finish, cost-effectiveness, and efficiency, powder coating from TOP Prototype is a popular choice for a wide range of applications.

As technology continues to advance, we can expect to see further improvements in powder coating technology offered by TOP Prototype, making it an even more attractive option for industries looking for sustainable and high-performance finishing solutions.