The Significance of CNC Machined Parts in the Automotive Field by TOP Prototype

In the highly competitive automotive industry, the pursuit of precision, quality, and innovation is unending. One of the key elements that has significantly contributed to the advancement of automotive manufacturing is the use of CNC machined parts. TOP Prototype, a renowned name in the manufacturing realm, has been at the forefront of providing high-quality CNC machined parts, playing a crucial role in the automotive sector.

The Precision and Quality Offered by CNC Machining

CNC (Computer Numerical Control) machining is a technology that allows for extremely accurate and consistent production of metal and plastic parts. It utilizes computer-programmed commands to control the movement of machine tools, ensuring that each part is manufactured to exact specifications. This level of precision is vital in the automotive industry, where even the slightest deviation in a part can affect the overall performance and safety of a vehicle.

TOP Prototype employs state-of-the-art CNC machining techniques and equipment to produce parts with tolerances as small as a few micrometers. For example, in the manufacturing of engine components such as pistons and cylinder heads, the precision provided by CNC machining ensures proper fit and function, leading to improved engine efficiency and reduced fuel consumption. The company’s strict quality control measures also guarantee that each part meets the highest industry standards, enhancing the reliability and durability of the automotive components.

Applications of CNC Machined Parts in Automotive Manufacturing

Engine Components

The engine is the heart of a vehicle, and CNC machined parts are integral to its performance. TOP Prototype manufactures a wide range of engine parts, including crankshafts, camshafts, and valve bodies. These parts are subjected to high stress and temperature during operation, and the precision of CNC machining ensures their strength and durability. The smooth surface finish achieved through CNC machining also reduces friction, further improving the engine’s efficiency and lifespan.

Transmission Systems

In the transmission system, accurate gears and shafts are essential for smooth power transfer. CNC machined gears produced by TOP Prototype have precise tooth profiles and dimensions, ensuring seamless engagement and efficient power transmission. This results in improved shifting performance and reduced noise and vibration, enhancing the overall driving experience. The company’s ability to produce complex transmission components with high precision has made it a preferred supplier for many automotive manufacturers.

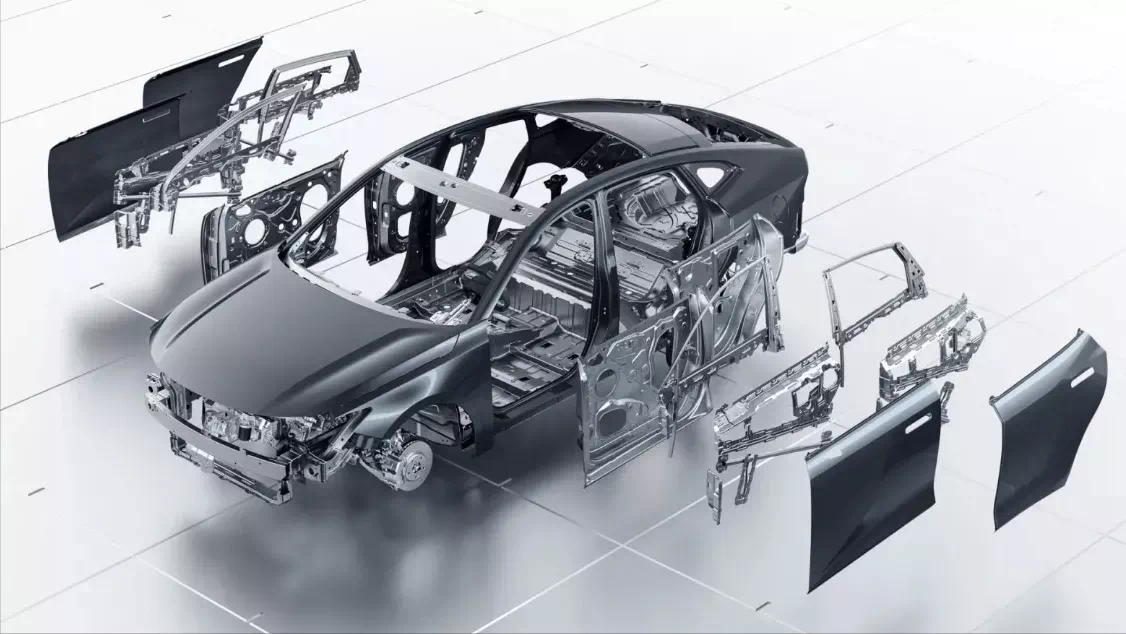

Suspension and Chassis Components

The suspension and chassis of a vehicle are responsible for providing stability and handling. CNC machined parts such as control arms, steering knuckles, and suspension brackets play a crucial role in maintaining the vehicle’s alignment and handling characteristics. TOP Prototype’s CNC machining capabilities allow for the production of lightweight yet strong components, improving the vehicle’s performance and fuel efficiency without compromising on safety and durability.

Interior and Exterior Trim

Beyond the mechanical components, CNC machining also finds applications in the production of automotive interior and exterior trim. TOP Prototype can create intricate and stylish designs for dashboard panels, door handles, and exterior emblems. The precision and flexibility of CNC machining enable the realization of complex geometries and fine details, adding a touch of elegance and uniqueness to the vehicle’s appearance.

The Role of TOP Prototype in the Automotive Supply Chain

TOP Prototype has established itself as a reliable and innovative partner in the automotive supply chain. The company’s commitment to quality, on-time delivery, and continuous improvement has made it a trusted supplier for many leading automotive brands. Its ability to work closely with customers from the design stage to the final production, providing technical support and expertise, has helped in the development of customized solutions that meet the specific requirements of different vehicles.

Moreover, TOP Prototype invests heavily in research and development to stay ahead of the curve in CNC machining technology. The company is constantly exploring new materials and manufacturing processes to improve the performance and cost-effectiveness of its products. By collaborating with automotive manufacturers and research institutions, TOP Prototype is contributing to the innovation and development of the entire automotive industry.

Challenges and Future Trends in CNC Machining for Automotive Parts

Challenges

Despite the many advantages of CNC machining, there are also some challenges in its application in the automotive field. One of the main challenges is the high cost of equipment and tooling, which can be a significant barrier for small and medium-sized enterprises. Additionally, the complexity of programming and operating CNC machines requires highly skilled technicians, which can lead to a shortage of qualified personnel in the industry.

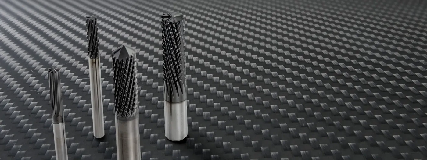

Another challenge is the increasing demand for lightweight and high-strength materials in the automotive industry. While CNC machining can handle a variety of materials, the processing of some advanced materials such as carbon fiber composites and titanium alloys can be more difficult and requires further research and development to optimize the machining parameters.

Future Trends

Looking ahead, the future of CNC machining in the automotive industry is promising. With the rapid development of digital technologies such as artificial intelligence and the Internet of Things, there is a growing trend towards the integration of these technologies with CNC machining. This will enable more intelligent manufacturing processes, such as predictive maintenance, real-time quality monitoring, and autonomous production.

In addition, the demand for customized and personalized vehicles is increasing. CNC machining’s flexibility and ability to produce small batches of customized parts will become more valuable in meeting this demand. TOP Prototype is well-positioned to capitalize on these trends by continuing to invest in technology and innovation, and by strengthening its partnerships with customers to provide more customized solutions.

In conclusion, CNC machined parts have become an indispensable part of the automotive manufacturing process, providing the precision, quality, and innovation needed to drive the industry forward.

TOP Prototype, with its advanced manufacturing capabilities and commitment to excellence, has made significant contributions to the automotive sector and will continue to play a crucial role in the future development of CNC machining in the automotive field. As the industry continues to evolve, the importance of CNC machining and companies like TOP Prototype will only grow, shaping the future of automotive manufacturing and performance.