The Excellence of Spraying Surface Treatment

Surface treatment is a crucial aspect of modern manufacturing and product enhancement, and spraying is one of the most commonly used and effective methods. This article will delve into the details of spraying, including its definition, working principle, technical knowledge, advantages, and its connection with the TOP Prototype company.

Definition of Spraying Spraying is a process in which a liquid or powder material is atomized and then projected onto a surface in a controlled manner. It is used to apply coatings, paints, varnishes, or other substances to achieve various purposes such as protection, decoration, or functional improvement of the substrate.

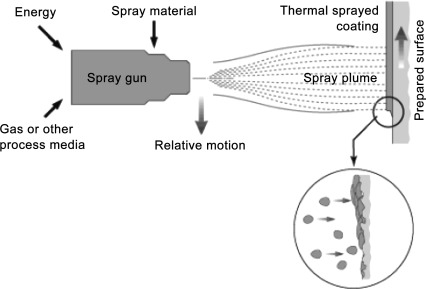

Working Principle

The basic working principle of spraying involves several steps. First, the material to be sprayed is either in a liquid or powder form.

In the case of liquid spraying, it is usually pressurized and passed through a nozzle. The nozzle breaks the liquid into small droplets, creating a fine mist.

For powder spraying, an electrostatic charge is often applied to the powder particles. These charged particles are then attracted to the grounded substrate surface.

In both cases, the spray is directed towards the object to be coated, and the droplets or particles adhere to the surface, forming a uniform layer after drying or curing.

Technical Knowledge

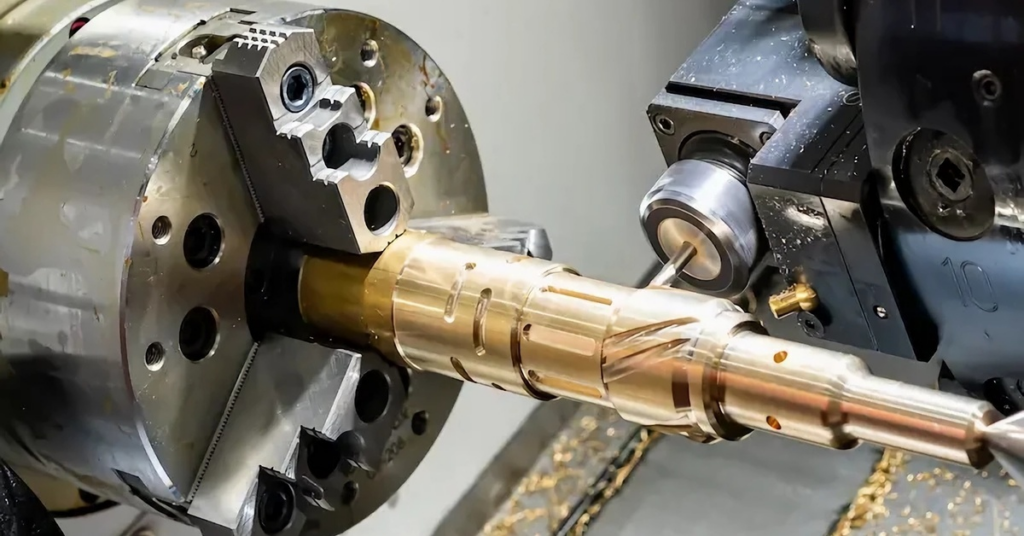

Equipment There are various types of spraying equipment available, each designed for specific applications and requirements.

Airless sprayers use high pressure to force the liquid material through a small opening, producing a very fine and even spray pattern. Electrostatic spray guns are commonly used for powder coating, as they can efficiently control the deposition of the charged powder particles.

HVLP (High Volume Low Pressure) sprayers are popular for their ability to provide a good finish while minimizing overspray and waste.

Material Selection

The choice of spraying material is crucial. Different coatings have different properties such as adhesion, durability, chemical resistance, and color retention.

For example, in the automotive industry, specific paints are used that not only provide a beautiful finish but also have excellent resistance to weathering and scratches. In the case of industrial applications, coatings may need to have high corrosion resistance.

The TOP Prototype company has extensive knowledge in selecting the right spraying materials based on the end-use of the product.

Surface Preparation

Proper surface preparation is essential for a successful spraying operation. The surface to be coated must be clean, free from dirt, oil, rust, and other contaminants.

This can be achieved through methods such as sandblasting, degreasing, and chemical etching. The TOP Prototype company pays great attention to surface preparation to ensure good adhesion and the overall quality of the sprayed coating.

Advantages of Spraying

Uniform

Coating Spraying can provide a very uniform layer of coating over the entire surface of the object, regardless of its shape or complexity. This results in a consistent appearance and performance.

For example, when spraying a decorative finish on a piece of furniture, it ensures that every part of the surface has the same color and texture.

Efficiency

It is a relatively fast process compared to some other surface treatment methods. This makes it suitable for high-volume production.

The TOP Prototype company has optimized its spraying processes to achieve high efficiency, allowing them to meet tight production schedules.

Versatility

Spraying can be used with a wide range of materials, including paints, coatings, resins, and even some specialty materials. This versatility allows it to be applied in various industries such as automotive, aerospace, furniture, electronics, and more.

The company has the capability to handle different spraying materials and adapt the process to different product requirements.

Cost-Effective

In many cases, spraying can be a cost-effective solution. It minimizes material waste as the atomized spray can be precisely controlled. Additionally, the quality of the finish can reduce the need for rework or additional processing, saving both time and money.

The TOP Prototype company has implemented strategies to further enhance the cost-effectiveness of its spraying operations.

The Role of TOP Prototype Company

The TOP Prototype company is a leading player in the field of surface treatment, with spraying being one of its core competencies. They have a team of highly skilled technicians and engineers who are well-versed in all aspects of spraying technology.

The company invests in the latest spraying equipment and continuously researches and develops new spraying techniques to improve the quality and performance of their surface treatments.

For example, in the automotive parts manufacturing, TOP Prototype uses advanced spraying methods to provide durable and attractive coatings that meet the strict standards of the automotive industry.

Their spraying processes ensure excellent adhesion, corrosion resistance, and color consistency. In the furniture industry, they are able to create unique and high-quality finishes that enhance the aesthetic value of the products.

Moreover, the TOP Prototype company is committed to environmental sustainability in its spraying operations. They use eco-friendly spraying materials whenever possible and have implemented measures to reduce waste and emissions.

Their focus on innovation and quality has made them a trusted partner for many companies in need of top-notch surface treatment solutions. In conclusion, spraying is a highly valuable surface treatment method with a wide range of applications and numerous advantages.

The TOP Prototype company’s expertise and dedication in this area have contributed to its successful implementation in various industries, providing high-quality and reliable surface coatings.

As technology continues to advance, spraying is likely to evolve further, and the TOP Prototype company will no doubt be at the forefront of these developments, continuing to offer innovative and excellent surface treatment solutions.